Cross Belt Magnetic Drum Separator

Permanent Magnetic Separator

Magnetic separator for removing ferrous impurities from free flowing solids

Cross belt magnetic drum separators are ideal for removing ferromagnetic contaminants, such as iron wires, sheets, or fine iron particles, from powdered, granular, or flake-like materials. They can also separate ferromagnetic pollutants that are coated by the material itself, achieving impurity removal rates of over 98%. This type of magnetic separation equipment is widely used in industries such as modified plastics and chemicals.

By utilizing a vibrating feeder, the material is evenly distributed across the conveyor belt. This ensures that the material stays in a relatively stationary position, even when a certain height of material accumulates. The combination of the magnetic drum and plate design ensures that ferromagnetic contaminants are efficiently captured and separated without being affected by the normal material flow. The cross belt magnetic separator is commonly used in post-processing stages of granulation, grinding, and powdering processes.

- Plastic Industry: Polyamide, modified plastics

- Chemical Industry: Magnesium oxide, PMMA, silicon micropowder, talc powder, antioxidants

| Model | |||||||

| Processing capacity | 2 | 3.5 | 5 | 3 | 5 | 7 | |

| Motor | Power | 0.55 | 0.75 | 1.1 | 0.75 | 0.75 | 1.1 |

| Rotation speed | 20-47 | 20-70 | 20-70 | 20-70 | 20-70 | 20-70 | |

| Voltage | 200V/3, 230V/3, 380V/3, Others | ||||||

| Frequency | 50Hz, 60Hz | ||||||

| Magnetic drum | 8000GS, 10000GS, 12000GS, 15000GS | ||||||

| Magnetic plate | 5000GS, 6000GS, 7000GS, 8000GS | ||||||

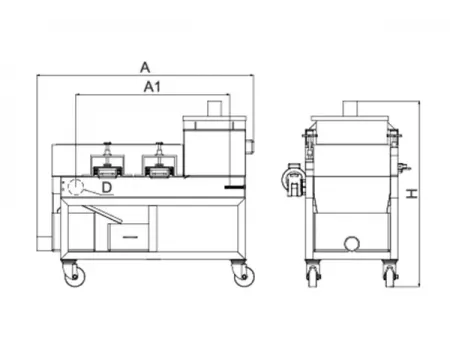

| Dimensions | D | Ø100 | Ø100 | Ø100 | Ø150 | Ø150 | Ø150 |

| A | 1450 | 1450 | 1450 | 1500 | 1500 | 1500 | |

| A1 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | |

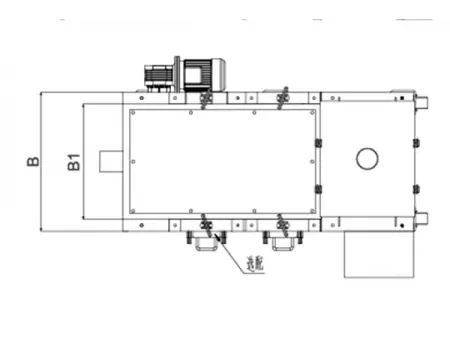

| B | 600 | 900 | 1100 | 600 | 900 | 1100 | |

| B1 | 500 | 800 | 1000 | 500 | 800 | 1000 | |

| H | 1200 | 1200 | 1200 | 1500 | 1500 | 1500 | |

| Customization | |||||||

- High ferrous contaminant removal rate (≥98%), ensuring excellent separation efficiency.

- Automatic ferrous contaminant separation, reducing the need for manual cleaning and increasing operational efficiency.

- Magnetic drum and plates made from Neodymium-Iron-Boron (NdFeB) magnets, offering a magnetic force range from 5000GS to 15000GS. Magnetic plates are also available as an optional feature.

- Customizable based on required processing volume, diameter, and size specifications.