Electric Drum Magnetic Separator

Permanent Magnetic Separator

Housed separating drum for continuous removal of ferrous impurities from bulk dry powder or granules

Electric drum magnetic separators are designed to remove ferromagnetic contaminants from large volumes of dry powders or granular materials. They are an excellent choice for high-throughput applications where materials contain a significant number of ferrous impurities. These magnet separators are widely used in industries such as plastics, food processing, chemicals, mining, and pharmaceuticals, where maintaining material purity and protecting equipment are critical.

Thanks to its continuous separation and self-cleaning functionality, this separator is commonly integrated into automated production lines. It is particularly effective in handling high-flow materials with elevated levels of ferrous contamination, ensuring efficient and uninterrupted operation.

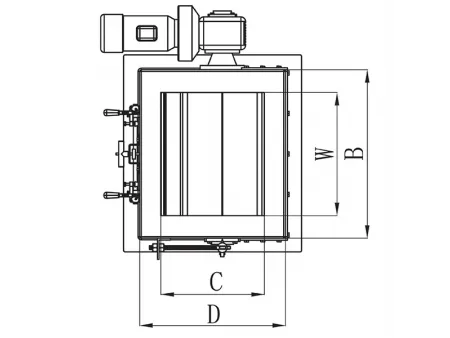

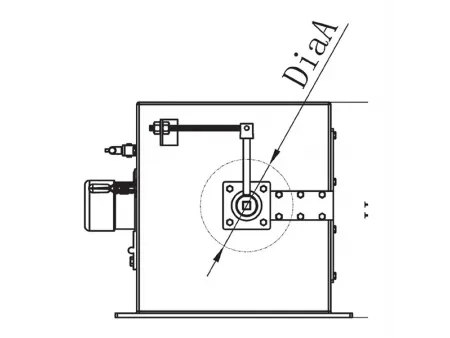

| Model | Dimensions (mm) | Weight (kg) | Power (kW) | |||||

| Dia. A | B | D | W | C | H | |||

| 215 | 420 | 450 | 280 | 290 | 500 | 105 | 0.25 | |

| 215 | 470 | 450 | 330 | 290 | 500 | 115 | 0.25 | |

| 215 | 520 | 450 | 380 | 290 | 500 | 125 | 0.25 | |

| 215 | 570 | 450 | 430 | 290 | 500 | 135 | 0.25 | |

| 215 | 620 | 450 | 480 | 290 | 500 | 145 | 0.25 | |

| 215 | 720 | 450 | 580 | 290 | 500 | 175 | 0.25 | |

| 215 | 820 | 450 | 680 | 290 | 500 | 195 | 0.25 | |

| 215 | 920 | 450 | 780 | 290 | 500 | 215 | 0.25 | |

| 215 | 1020 | 450 | 880 | 290 | 500 | 225 | 0.37 | |

| 215 | 1120 | 450 | 980 | 290 | 500 | 245 | 0.37 | |

| 315 | 420 | 550 | 280 | 360 | 650 | 218 | 0.25 | |

| 315 | 470 | 550 | 330 | 360 | 650 | 235 | 0.25 | |

| 315 | 520 | 550 | 380 | 360 | 650 | 252 | 0.25 | |

| 315 | 570 | 550 | 430 | 360 | 650 | 269 | 0.25 | |

| 315 | 620 | 550 | 480 | 360 | 650 | 286 | 0.25 | |

| 315 | 720 | 550 | 580 | 360 | 650 | 320 | 0.25 | |

| 315 | 820 | 550 | 680 | 360 | 650 | 354 | 0.37 | |

| 315 | 920 | 550 | 780 | 360 | 650 | 388 | 0.37 | |

| 315 | 1020 | 550 | 880 | 360 | 650 | 422 | 0.37 | |

| 315 | 1120 | 550 | 980 | 360 | 650 | 456 | 0.55 | |

| 315 | 1220 | 550 | 1080 | 360 | 650 | 490 | 0.55 | |

| 400 | 420 | 635 | 280 | 435 | 800 | 288 | 0.37 | |

| 400 | 470 | 635 | 330 | 435 | 800 | 314 | 0.37 | |

| 400 | 520 | 635 | 380 | 435 | 800 | 340 | 0.37 | |

| 400 | 570 | 635 | 430 | 435 | 800 | 366 | 0.55 | |

| 400 | 620 | 635 | 480 | 435 | 800 | 392 | 0.55 | |

| 400 | 720 | 635 | 580 | 435 | 800 | 444 | 0.55 | |

| 400 | 820 | 635 | 680 | 435 | 800 | 496 | 0.55 | |

| 400 | 920 | 635 | 780 | 435 | 800 | 548 | 0.55 | |

| 400 | 1020 | 635 | 880 | 435 | 800 | 600 | 0.55 | |

| 400 | 1120 | 635 | 980 | 435 | 800 | 652 | 0.75 | |

| 400 | 1220 | 635 | 1080 | 435 | 800 | 704 | 0.75 | |

| 400 | 1320 | 635 | 1180 | 435 | 800 | 756 | 0.75 | |

- The separation process is driven by a gear motor, ensuring reliable and consistent performance.

- Adjustable speed and magnetic field angle allow for optimization of separation efficiency based on material characteristics.

- Continuous separation and automatic cleaning, making it well-suited for fully automated production lines with minimal manual intervention.

- Customizable magnetic strength, inlet, and outlet configurations can be tailored to meet specific processing needs.