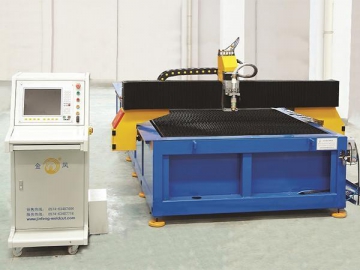

PSG200 Plasma Cutting Machine

Application

The PSG200 plasma cutting machine has the following advantages: the plasma arc has more concentrated heat, higher temperature, faster cutting speed and small deformation. It can also be used to cut stainless steel, aluminum etc. It is suitable for cutting various sheet parts and small sized metal parts.

| Base machine | |

| Machine specification | 2000mm |

| Rail length | 4000mm |

| CNC controller | |

| CNC system | CHINESE OR HYPERTHERM USA |

| Nesting software | 1set, FastCAM auto nesting and programming,Australia |

| Plasma cutting system | |

| Cutting torch carriage | 1set, China |

| Plasma arc voltage height sensor | 1 set, JF Sensor THC, automation height control |

| Plasma power source | 1unit, MAX200PRO, HYPERTHERM USA |

| Plasma cutting torch | 1set |

| Drive mode | Dual drive |

| Transverse drive servo motor | Panasonic |

| Longitudinal drive servo motor | Panasonic |

| Servo drive system | Panasonic |

| Transverse planetary gearbox | Shimpo |

| Longitudinal planetary gearbox | Shimpo |

| Nesting programming software | FastCAM, Australia |

| PLC | Delta,Taiwan |

| CNC control system | MicroEDGEPRO, Hyertherm, USA |

| Plasma power source | HYPERTHERM USA |

| Plasma arc-voltage height sensor | JINFENG CHINA |

| Main electric part | Schneider |

Features and technical description

The PSG200 plasma cutting machine has the following features

1. It has an integral cutting table which has more stable cutting, so that the cutting precision is improved.

2. There is optional 80W low power plasma power source or 200W plasma power source, improving the cutting speed and precision of sheet metal.

3. It is equipped with shallow water tank which is used for cutting dust absorption so that it is environment friendly. It can also be equipped with additional dust removal system according to customers' requirements.

Jinfeng introduction

Jinfeng Welding & Cutting Machinery Manufacture Co., Ltd has mechanical department, electrical department and software department. There are 80 people in the team in total. We also hire senior engineers from ESAB to carry out joint development and design of various structural steel H beam production lines, so that we have technical guarantee.

Jinfeng has strong production capacity: we have 13 imported CNC machining centers, 3 4mx12m large machining centers, so that the annual output of various cutting machine is 1000.

All the members of the sales team have more than 10 years of experience in service, so that they can provide customers with various consultation and services in time. Besides, Jinfeng is equipped with an after-sales service team of 30 employees, so that they can provide 24-hour after-sales service all year round.