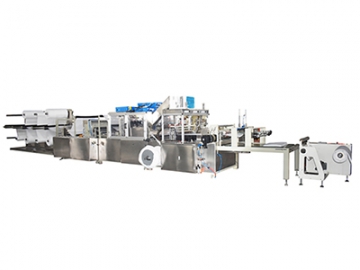

Semi Automatic Non-woven Zipper Bag Making Machine, WFB-L600

Zipper Bag Maker/ Plastic Zipper Bag Machine/ Bag Production Equipment

Main Introductions

The semi-automatic non-woven zipper bag making machine uses ultrasonic sealing for PP non-woven fabric materials. It can make non-woven zipper bags, D-cut bags, flat bags, etc.

Applied Materials

PP non-woven fabric, regeneration non-woven, transparent BOPP, OPP material.

Printed or non-printed.

Characteristic

1. The speed of non-woven zipper bag(60pcs/min), D-cut bag(90pcs/min), flat bag(70pcs/min), etc.

2. The computer controlled functions such as photoelectric tracking, automatic positioning and automatic edging make the equipment more accurate and stable.

3. Automatic counting system allows you to complete orders as directed while minimizing waste.

4. Highly environmentally friendly.

Procedure

Raw material - Bag mouth fold - Thermal bonding - side fold - Bottom sealing - thermal bonding - edge cut - bag cut - collection

| Model | WFB-L600 |

| Max. Bag Making Width | 600mm |

| Bag Making Thickness Range | 20-100g |

| Max. Bag Making Length | 999mm |

| Speed | 40-60pcs/min |

| Total Power | 8kw |

| Weight of Machine | 2.5t |

| Overall Dimensions | 7800*1700*2000mm |

FAQ:

Q: Is the machine easily operated?

A: It is operated by computer control very easily.

Q: How long is the delivery time?

A: The delivery time is usually 15 days.

Q: What about package and delivery?

A: With plastic film and wooden foot packing.

Q: Can I use other material with non-woven production?

A: No, you can’t. Only BOPP and OPP material.