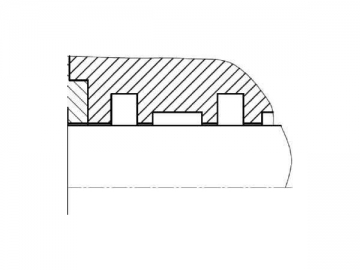

Single/Double Lip Wiper Seal

Wipe seals are called a lot of different names. Dust seals, rod scrapers, and rod wipers are just a few. Regardless of what it is called, the wiper seal either in single or double lip design, is a critical part of a hydraulic cylinder when exposed to dust, debris and outside weather conditions.

In its most basic form, the wiper seal is a combo of PTFE filled lip seal and rubber o-ring. The sealing device seals out dust, grit, ice pellets and other contaminants, and is typically used with a Stepseal to remove remaining lubricating film from the piston rod.

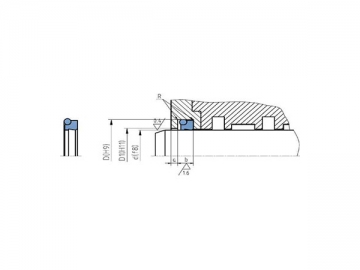

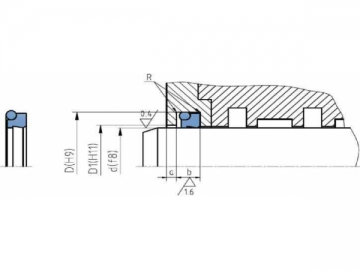

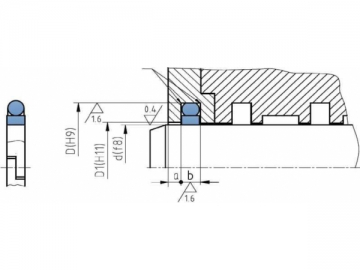

Currently available are three rod scraper configurations, heavy-duty double lip, general-purpose double lip, and single lip.

Model Selection

This o-ring energized scraper fits around piston rods in 19mm to 1000mm diameter. Suitable for severe dusty conditions as well as high speed reciprocating applications.

Operating Conditions

Operating Temperature: -55~ 250°C (depending on the o-ring material)

Reciprocating speed: <6 m/s

Operating media: mud, sand, filth, etc.

Related Specs

| Rod diameter d(f8) | Groove diameter (Housing diameter)D(H9) | Groove width b 02 | O-ring diameter d2 | Throat diameter D1(H11) | Outer Throat Depth a^ | Round R^ |

| 19 ~ 39 | d 7.6 | 4.2 | 1.80 | d 1.5 | 3 | 0.5 |

| 40 ~ 69 | d 8.8 | 6.3 | 2.65 | d 1.5 | 3 | 0.6 |

| 70~139 | d 12.2 | 8.1 | 3.55 | d 2.0 | 4 | 0.7 |

| 140 ~ 399 | d 16.0 | 9.5 | 5.30 | d 2.5 | 5 | 0.8 |

| 400 ~ 649 | d 24.0 | 14.0 | 7.00 | d 2.5 | 8 | 1.2 |

| 650 ~ 1000 | d 27.3 | 16.0 | 8.60 | d 2.5 | 10 | 1.5 |

Suitable for reciprocating, swiveling, or rotary applications that contain light to mid-level of contamination. Do not use this wiper seal in heavy-filth environments.

Operating Conditions

Operating temperature: -55~ 250°C (depending on the o-ring material)

Operating speed: <6m/s

Operating media: mud, sand, filth, etc.

Related Specs

| Rod diameter d(f8) | Groove diameter (Housing diameter) D(H9) | Groove width b 02 | O-ring diameter d2 | Throat diameter D1(H11) | Outer Throat Depth a^ | Round R^ |

| 6 ~ 11 | d 4.8 | 3.7 | 1.80 | d 1.0 | 2 | 0.4 |

| 12 ~ 64 | d 6.8 | 5.0 | 2.65 | d 1.5 | 2 | 0.5 |

| 65 ~ 250 | d 8.8 | 6.0 | 3.55 | d 1.5 | 3 | 0.5 |

| 251-420 | d 12.2 | 8.4 | 5.30 | d 2.0 | 4 | 0.8 |

| 421-650 | d 16.0 | 11.0 | 7.00 | d 2.0 | 4 | 1.2 |

| 651-1000 | d 20.0 | 14.0 | 8.60 | d 2.5 | 5 | 1.5 |

Scrapes dust off of the piston rod in reciprocating, swiveling, or rotary applications.

Operating Conditions

Operating temperature: -55~ 250°C (depending on the o-ring material)

Operating speed: <6m/s

Operating media: mud, sand, filth, etc.

Related Specs

| Rod diameter d(f8) | Groove diameter D(H9) | Groove width b 02 | O-ring diameter d2 | Throat diameter D1(H11) | Outer Throat Depth a^ | Round R^ |

| 6 ~ 11 | d 4.8 | 3.7 | 1.80 | d 2.7 | 2 | 0.4 |

| 12 ~ 64 | d 6.8 | 5.0 | 2.65 | d 3.5 | 2 | 0.5 |

| 65~250 | d 8.8 | 6.0 | 3.55 | d 4.0 | 3 | 0.5 |

| 251-420 | d 12.2 | 8.4 | 5.30 | d 4.5 | 3 | 0.8 |

| 421-650 | d 16.0 | 11.0 | 7.00 | d 5.2 | 4 | 1.2 |

| 651-1000 | d 20.0 | 14.0 | 8.60 | d 6.6 | 5 | 1.5 |