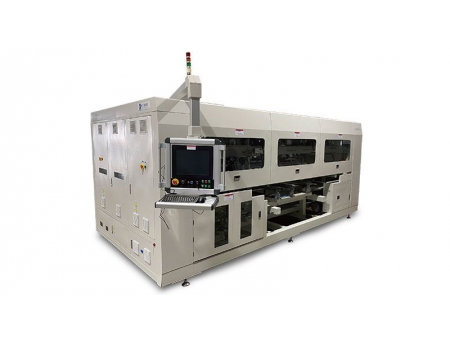

Automatic Bussing Machine

Request a Quote

Used for automatic interconnection of PV cell strings

An automatic bussing machine adopts induction welding and can be applied to 5BB-12BB solar cells of 156-210mm. The soldering precision is high. The busbar overlap area exceeds 80%, and the deviation is ±1mm. The bussing machine features a small size and is suitable for safe and stable production of various solar strings. The soldering stringer is an indispensible machine for solar string production.

Technical Parameters

| Item | Parameters |

| Cell type | 156mm-210mm/5BB-12BB |

| Panel size | 2,500mm*1,400mm |

| Busbar specification | Roll feeding and automatic cutting; thickness 0.18-0.45mm; Width 4mm, 5mm, 6mm, 8mm; roller weight≤13kg |

| Cycle time | 20s for conventional welding; 25s for bypass welding |

| Breakage rate | < 0.2% |

| Soldering method | Induction soldering |

| Lead busbar angle and deviation | 90°; deviation≤2° |

| Busbar overlap area | ≥80%, and the deviation is within ± 1 mm |

| Overlap deviation of bypass bus belt | ±1mm |

| Secondary string layup accuracy | ±0.25mm |

| Utilization rate | ≥98% |

| Overall dimensions (L*W*H) | 4,930*4,613*2,641mm |

| Voltage | 3 phase 5 wire 380V, 50/60Hz |

| Power | Average 22kW; Peak 30kW |

| Air pressure | 0.6-0.8MPa 2.0m3/min |

Features

- Separating the cell string from the glass, and grabbing the cell string in the air with its head, middle and tail exposed to be soldered with busbar at a certain height;

- Bypass busbar for 5 strings of 1/3 210mm cells;

- Rolling bus belt supply and U and L-shaped lead bending for different processing needs;

- The function of bus belt drilling can be turned on or off as customer needs;

- The assembly line in front of the welding machine ensures the accurate positioning of solar panels to improve soldering quality.