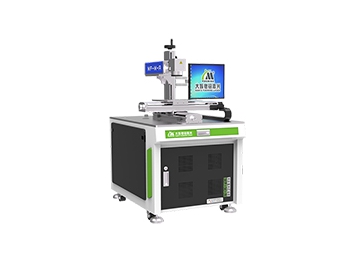

Laser Marking Machine

Laser Marking Machine VML-FPS/FHS/FVS/FDS

Capital letters followed by what they stand for

F-Fiber, P-Portable, H-Hand-hold, V-Vertical, D-Desktop

Photos of VICUT Laser Cutting Machine

- VML-FHS

- VML-FPS

- Available Options-

Elevating Platform - VML-FDS

- VML-FVS

Marking metal or nonmetal materials with laser is easy, fast and provides accurate control over size, depth and shape of laser marks on the parts being lasered. VICUT laser marking machine uses a fiber laser to deliver highly-focused quality laser beam to get the marking of delicate items done. Buy a small-size VICUT laser machine and watch it pay for itself in a short period as the laser consumes very little power while being able to engrave on all kinds of materials.

Applicable Industries for Laser Marking Machine

Mobile phone keypad, plastic keys, electronic components, integrated circuits (IC), electrical appliances, communication products, sanitary ware, tools, accessories, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils, stainless steel products, among others.

What materials is VICUT laser marker used on?

Metals (including precious metals), engineering plastics, electroplating materials, coating materials, ordinary plastics, rubber, epoxy resin, ceramic, plastic, ABS, PVC, PES, steel, titanium, copper and other materials

Features of VICUT Laser Marking Machine

1. Highly focused, diffraction-limited laser beam suits the laser marking machine for highly detailed marking. Operating on the fundamental transverse mode (also known as TEM00 mode), the laser has a M2 factor close to 1. With a low beam divergence only 1/4 that of a diode laser, VICUT fiber laser also has a spot size of focus no more than 20µm.

2. High pulse repletion rate as well as stable laser power ensures high-speed laser marking. Unit pulse power surge is lower than 1%. Besides, it is easy to control laser dot size, depth and shape.

3. In the same time that it takes to mark an item with other marking techniques, laser marking machine can turn out 2 to 3 beautifully laser-marked items.

4. Air cooled, small-size

5. Long lifetime. Ultra-low power consumption of 0.5kw. Energy conversion efficiency is more than 30 % (not suitable for stainless steel color marking).

Technical Specifications of Laser Marking Machine

| Model | ||||

| Laser Power | 10W/20W/30W | |||

| Laser Wavelength | 1064nm | |||

| Q-frequency | 20KHz~30KHz | |||

| Divergence | 0.3mard | |||

| Marking Range | 100×100mm(200×200mm/300×300mm is optional) | |||

| Minimum Line Width | 0.02mm | |||

| Minimum Character | 0.15mm | |||

| Marking Depth | 0 ~0.5mm | |||

| Engraving Line Speed | ≤7000mm/s | |||

| Repeatability | ±0.001mm | |||

| Beam Quality | M2:1.2~1.8 | |||

| Types of Marks | Graphics, texts, bar codes, two-dimensional code. Automatically marking the date, batch number, serial number, frequency, etc. | |||

| Graphic Format Supported | bmp, jpg, gif, tga, png, tif, ai, dxf, dst, plt, etc. | |||

| Working Voltage | 220V±10%/50Hz/4A | |||

| Unit Power | <0.5kw | |||

| Environmental Performance | Clean, dust free or dustless | |||

| Working Condition: Humidity | 5%-75%, free of condensed water | |||

| Laser Module Life | >100000 hours | |||

| Optional Functions | 1. Laser power Q frequency can be adjusted from 20KHz~80KHz. Color marking is available. 2. German IPG fiber laser power 3. Rotary attachment (80mm in diameter) 4. Computer 5. CTI Garvo Head | |||

Laser Marked Samples

Aaluminum marking