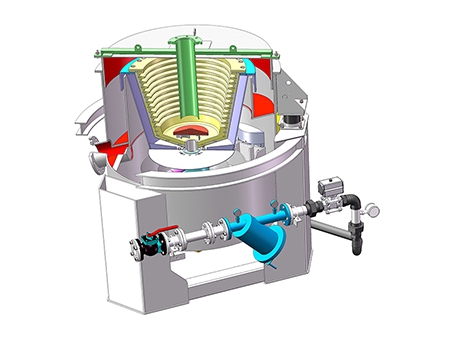

Centrifugal Gravity Concentrator

Centrifugal concentrator (centrifugal separator) is a kind of high efficiency gravity concentrating equipment. High-speed rotation generates very strong centrifugal force to intensify gravity separation which makes more effective recovery of the fine heavies.

- Fluidized water is used to keep the separation bed in suspension.

- Unattended automation.

- The speed of the concentration cone is adjustable for different fineness free gold.

- Best concentration ratio and high recovery rate.

- PU concentration cone ensures long service life and operational stability.

The centrifugal concentrator can be installed either indoors or outdoors to be operated without any trouble affected by the environment and geographical conditions. It can be used to recover coarse and fine gold in single gravity concentration system, milling system before flotation or cyanide leaching, tailings recovery system, alluvial / placer gold washing system, and concentrate enrichment system.

It can also be installed on the trailer to make a mobile concentrator, or combines with pumps, vibrating screen, ball mill and other equipment to form a skid mounted modular processing plant.

The centrifugal concentrators are divided into three product categories: Basic Type (BLX), Semi-Automatic Type (SLX) and Automatic Type (ALX) to meet the demands of different customers. All of them can achieve the optimal gold recovery target.

| Type | Basic (BLX) | Semi-Automatic (SLX) | Automatic (ALX) |

| Material of Concentration Cone | Stainless Steel | Stainless Steel Shell Polyurethane Core | Stainless Steel Shell Polyurethane Core |

| Fluidized Water | Radial Entry, More Consumption | Oblique Entry, Less Consumption | Oblique Entry, Less Consumption |

| Automation | Null | Semi Automation, Long Time to Discharge Concentrate | Unattended |

| G Force | 60 | 60 | 60-90 Adjusted |

| Fault Detection | Null | Partial | Multi Points Detection and Fault Alarm |

| Applications | Granular Gold | Granular, Micro Fine and Wrapped Gold | Granular, Micro Fine and Wrapped Gold |

| Model | BLX-12 SLX-12 | SLX-XD20 ALX-XD20 | SLX-XD30 ALX-XD30 | SLX-XD40 ALX-XD40 | SLX-Q48 ALX-Q48 |

| Solid Capacity (t/h) | 5-18 | 15-75 | 70-155 | 110-210 | 180-380 |

| Feed Particle Size (*mm) | 0-2 | 0-2 | 0-1.7 recommended, Max 6 | ||

| Solid Concentration of Feed Slurry (W/W, %) | 0-65 | 0-70 | 0-75 | 0-75 | 0-75 |

| Max. Slurry Capacity (m3/h) | 25 | 100 | 218 | 325 | 540 |

| Fluidized water Consumption (m3/h) | 4.5-6.5 | 10-16 | 22-32 | 25-45 | 45-65 |

| Concentrate Discharge Cycle (h) | 1-10 | 1-10 | 1-10 | 1-10 | 1-10 |

| Concentrate Mass per Batch Cycle (kg) | 2.7-4.8 | 8-12 | 22-29 | 35-62 | 45-65 |

| Power (kW) | 2.2-5.5 | 5.5-7.5 | 11-22 | 30-45 | 45-75 |