O-Ring Loaded U-Cup

Mating a U-cup with an O-ring to create an O-ring loaded U-cup helps simplify the seal design with one part instead of two, ease installation, and prevent tolerance stack-up. The U-cup seal is filled with PTFE, while the rubber O-ring measures up to GB/T3452.1-2005 standards. Typical uses for this o-ring loaded u-cup are on the reciprocating piston rod in a hydraulic or pneumatic system. From there, the product gets another name: rod seal.

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

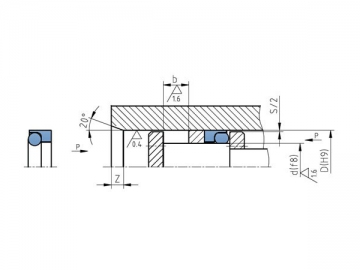

O-ring loaded seal installation diagram

Related Specs

| Rod diameter d(f8) | Groove diameter D(H9) | Groove width b 0.2 | O-ring diameter d 2 | Radial clearance S≤ | Chamfer Z≥ |

| 7~17 ① | d 6.0 | 5.8 | 2.65 | 0.3 | 3 |

| 18~39 ① | d 8.0 | 6.8 | 3.55 | 0.3 | 5 |

| 40~108 | d 12.6 | 9.2 | 5.30 | 0.4 | 7 |

| 109~670 | d 16.4 | 12.7 | 7.00 | 0.4 | 10 |

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

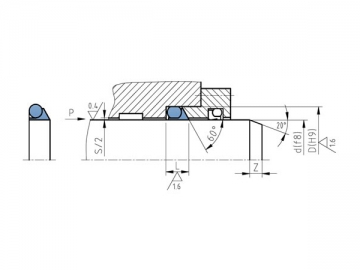

O-ring loaded seal installation diagram

Related Specs

| Rod diameter d(f8) | Groove diameter D(H9) | Groove width b 0.2 | O-ring diameter d 2 | Radial clearance S≤ | Chamfer Z≥ |

| 22~39 ① | d 8.0 | 6.8 | 3.5 | 0.3 | 5 |

| 40~150 | d 13.2 | 9.8 | 5.7 | 0.4 | 7 |

| 151~1000 | d 19.2 | 15.6 | 8.6 | 0.5 | 10 |

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

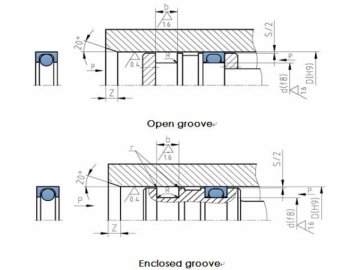

O-ring loaded seal installation diagram

Related Specs

| Cylinder diameter D(H9) | Groove diameter d(f8) | Groove width b 0.2 | O-ring diameter d 2 | Radial clearance S≤ | Chamfer Z≥ |

| 13~23 ① | D-6.0 | 5.8 | 2.65 | 0.3 | 3 |

| 24~48 ① | D-8.0 | 6.8 | 3.55 | 0.3 | 5 |

| 20~127 | D-12.6 | 9.2 | 5.30 | 0.4 | 7 |

| 128~690 | D-16.4 | 12.7 | 7.00 | 0.5 | 10 |

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Cylinder diameter D(H9) | Groove diameter d(f8) | Groove width b 0.2 | O-ring diameter d 2 | Radial clearance S≤ | Chamfer Z≥ |

| 24~48 ① | D-8.0 | 6.8 | 3.5 | 0.3 | 5 |

| 20~169 | D-13.2 | 9.8 | 5.7 | 0.4 | 7 |

| 170~1000 | D-19.2 | 15.6 | 8.6 | 0.5 | 10 |

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Groove outside diameter D(H11) | Groove width b 0.2 | Groove depth h 0.1 | O-ring diameter d 2 | Round R |

| 19~31 | 5.8 | 3.0 | 2.65 | 0.3~0.4 |

| 32~59 | 6.8 | 4.0 | 3.55 | 0.4~0.6 |

| 60~134 | 9.2 | 6.1 | 5.30 | 0.6~0.8 |

| 135~670 | 12.6 | 8.1 | 7.00 | 0.8~0.1.2 |

Operating Conditions

Operating pressure: 0~300MPa

Operating temperature: -55~ 250°C (depending on the type of o-ring material)

Reciprocating speed: ≤6 m/s

Operating media: air, water, ethylene glycol based water solution, mineral oil, acid, alkali, etc.

O-ring loaded seal installation diagram

Related Specs

| Groove diameter D(H11) | Groove width b 0.2 | Groove depth h 0.1 | O-ring diameter d 2 | Round R |

| 36~59 | 6.8 | 4.0 | 3.5 | 0.3~0.5 |

| 60~181 | 9.8 | 6.6 | 5.7 | 0.6~0.8 |

| 182~500 | 15.5 | 9.5 | 8.6 | 0.8~1.2 |