Components for tissue machinery

Request a Quote

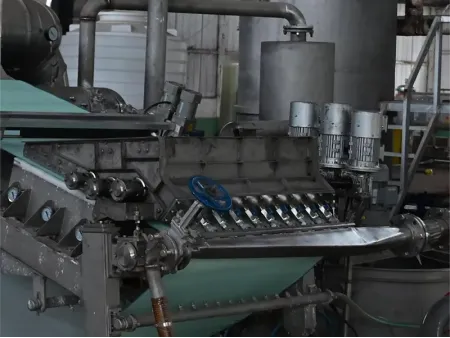

Paper machine headbox for inclined wire machine

The inclined wire headbox is paired with the specially designed former used in the Inclined wire paper machine. The inclined wire headbox is composed of a stock distribution pipe, turbulence roller, lip plate, side wall plate, etc. The parts in contact with the pulp are made of stainless steel or organic glass with polished surfaces.

The inclined wire headbox is suitable for an .

Specifications

| Working Width | 800-4200mm |

| Headbox Pond Width | 800-4200mm |

| Working Speed | 10-300m/min |

| Consistency | 0.1-0.5% |

| Max. Recirculation Flow | 10-15% |

Features

- The equal pressure taper stock distribution pipe ensures consistent pressure across the width of the headbox.

- To prevent pulp flocculation, there are three micro-turbulence rollers installed, which create gentle turbulence to ensure uniform mixing of the pulp without causing any significant disturbance.

- The angle of stock delivery can be freely adjusted within the range of 0 to 30 degrees.

- The entire headbox is made of stainless steel, and the surfaces that come into contact with pulp are meticulously mirror polished, preventing pulp adhesion and scaling.

- Inclined wire headbox can be equipped with a water dilution unit to achieve automatic regulation of cross-sectional basis weight.

Paper Machine Components Customized to Meet Various Requirements

The headbox is a key component of the paper making machine, playing a crucial role in ensuring the production of high-quality paper. We would be delighted to partner with your esteemed team to develop cutting-edge accessories that are tailored to meet your unique papermaking requirements. By working together, we can further optimize the paper production process and attain even higher benchmarks of quality.