Coated Glass

We specialize in coated glass, which involves applying one or more layers of metal, alloy, or metal compound films to the glass surface to modify its optical properties and meet specific requirements. Our primary product is low-emissivity (low-E) glass, available in both offline and online low-E coated glass. Proudly, we are among the few companies that possess both offline and online coating technologies, operating three online coating production lines with a daily capacity of 1,800 tons and two offline coating production lines with an annual capacity of 20 million square meters.

We excel in producing low-E glass, which features a low-reflectivity coating applied through advanced physical or chemical methods to enhance its thermal performance. We utilize two processing technologies for manufacturing low-E glass: vacuum cathode magnetron sputtering (a physical method, also known as offline low-E or Soft low-E glass) and chemical vapor deposition (a chemical method, also known as online Low-E or Hard Low-E glass). Our expertise spans both techniques, offering a wide range of low-E glass solutions tailored to meet specific thermal and optical requirements.

| ITEMS | Offline Low-E Glass | Online Low-E Glass |

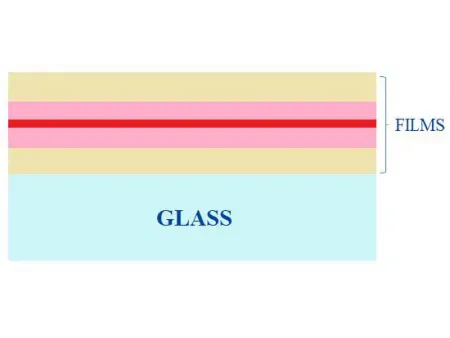

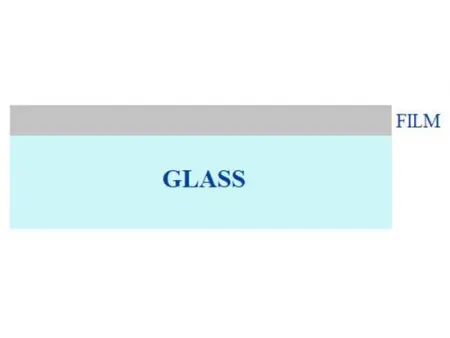

| Production techniques | 1. Vacuum cathode magnetron sputtering process 2. Independent coating glass production lines 3, Multi-layer composite coatings on the glass surface | 1. Chemical vapor deposition method 2. Preparation in the float line tin bath 3. Single-layer coating |

| Coating structure | ||

| Appearance and performance | We offer extensive choices with a wide range of colors and performance specifications. | We offer simplified choices with fixed appearance colors and specifications. |

| Coating stability and processability | 1. Silver coating is prone to oxidation but can be preserved for 1-2 years with professional packaging. 2. The glass must be used as an IGU, with the silver coating facing indoor. 3. In special cases, our triple-silver coating products can be used in laminated glass and can be in direct contact with the silver coating. | 1. Prepared in the float line tin bath, the coating is firmly bonded to the glass, making it as stable and durable as float glass, with similar storage conditions. 2. The glass allows the application as a single sheet and is easy to process, with processing methods similar to float glass. |

| Jinjing flagship glass products | US1.16, UD49, UD68, UD80, SOLARBAN70, SOLARBAN 72 | EazyTek |

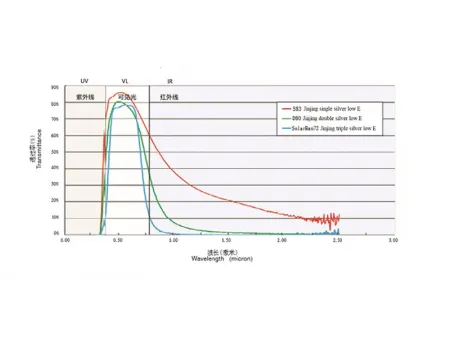

The chart shows the solar spectrum transmittance curves of single-silver, double-silver, and triple-silver low-E glass, with similar visible light transmittance in the 380-780 nm range. The middle vertical line represents the visible light region, while the area to the right represents the infrared region (780-2500 nm). Since most heat is carried by infrared radiation, the area under the curve reflects the solar energy transmitted directly through the glass. The area is largest for single-silver low-E, followed by double-silver low-E, and smallest for triple-silver low-E, indicating that triple-silver low-E allows the least heat transfer, offering superior thermal insulation performance.

The curves in the chart represent the solar spectrum transmittance from 380-2500 nm where the SHGC values are similar for single-silver, double-silver, and triple-silver low-E glass. While SHGC values are comparable, indicating similar total solar heat gain, the distribution shapes of the curves differ significantly. Triple-silver low-E covers the smallest area under the curve, indicating the lowest heat transfer through the glass. This means that triple-silver low-E glass provides significantly better shielding against infrared heat radiation compared to double- and single-silver low-E glass, greatly improving indoor comfort during summer.