Grinding Wheels

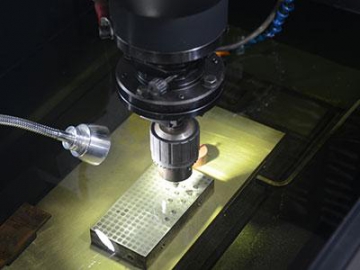

Hongtuo's grinding wheels include CBN grinding wheels anddiamond wheels. Basic characteristics of these abrasive wheels include each featuring a high hardness, a high thermal conductivity, and high sharpness. In comparison to common grinding wheels, CBN and diamond grinding wheels offer a higher abrasive cutting efficiency. Because of that,this bonded abrasive tool is suitable for high efficiency and high rate grinding in modern machining works.

Hardness comparison of various abrasives is as followsIf you wish to purchase grinding wheels from us, apart from the basic size, we need to know the abrasive particle size, density and bonded agent type.

| CHINA | INTERNATIONAL | FEPA | AMERICA | JAPAN | WEST GERMANY | RUSSIA | ||||||||

| GB 6406-86 | ISO 6106-1979 | ANSI B74. 16-1971 | JIS 4130-1982 | DIN 848-1988 | ROCT 9206-80 | |||||||||

| Grit No. | Grain Size | Grit No. 1 | Grit No. 2 | Grain Size | Grit No. | Grain Size | Grit No. | Grain Size | Grit No. | Grain Size | Grit No. | Grain Size | Girt No. | Grain Size |

| 1O/18 | 1180/1000 | 1181 | 16/18 | 1180/1000 | D1181 | 1180/1000 | 16/18 | 1180/1000 | 16/18 | 1180/1000 | D1180 | 1180/1000 | 2500/2000 | 2500/2000 |

| 18/20 | 1000/850 | 1001 | 18/20 | 1000/850 | D1001 | 1000/850 | 18/20 | 1000/850 | 18/20 | 1000/850 | D1001 | 1000/850 | 2000/1600 | 2000/1600 |

| 20/25 | 850/710 | 851 | - | 850/710 | D851 | 850/710 | 20/30 | 850/600 | 20/30 | 850/600 | D851 | 850/710 | 1600/1250 | 1600/1250 |

| 25/30 | 710/600 | 711 | - | 710/600 | D711 | 710/600 | D711 | 710/600 | 1250/1000 | 1250/1000 | ||||

| 30/35 | 600/500 | 601 | - | 600/500 | D601 | 600/500 | 30/40 | 600/425 | 30/40 | 600/425 | D601 | 600/500 | 1000/800 | 1000/800 |

| 35/40 | 500/425 | 501 | - | 500/425 | D501 | 500/425 | D501 | 500/425 | 800/630 | 800/630 | ||||

| 40/45 | 425/355 | 426 | - | 425/355 | D426 | 425/355 | 40/50 | 425/300 | 40/50 | 425/300 | D426 | 425/355 | 630/500 | 630/500 |

| 45/50 | 355/300 | 356 | - | 355/300 | D356 | 355/300 | D356 | 355/300 | 500/400 | 500/400 | ||||

| 50/60 | 300/250 | 301 | 50/60 | 300/250 | D301 | 300/250 | 50/60 | 300/250 | 50/60 | 300/250 | D301 | 300/250 | 400/315 | 400/315 |

| 60/70 | 250/212 | 251 | - | 250/212 | D251 | 250/212 | 60/80 | 250/180 | 60/80 | 250/180 | D251 | 250/212 | 315/250 | 315/250 |

| 70/80 | 212/180 | 213 | - | 212/180 | D213 | 212/180 | D213 | 212/180 | 250/200 | 250/200 | ||||

| 80/100 | 180/150 | 181 | 80/100 | 180/150 | D181 | 180/150 | 80/100 | 180/150 | 80/100 | 180/150 | D181 | 180/150 | 200/160 | 200/160 |

| 100/120 | 150/125 | 151 | 100/120 | 150/125 | D151 | 150/125 | 100/120 | 150/125 | 100/120 | 150/125 | D151 | 150/125 | 160/125 | 160/125 |

| 120/140 | 125/106 | 126 | 120/140 | 125/106 | D126 | 125/106 | 120/140 | 125/106 | 120/140 | 125/106 | D126 | 125/106 | 125/100 | 125/100 |

| 140/170 | 106/90 | 107 | 140/170 | 106/90 | D107 | 106/90 | 140/170 | 106/90 | 140/170 | 106/90 | D107 | 106/90 | 100/80 | 100/80 |

| 170/200 | 90/75 | 91 | 170/200 | 90/75 | D91 | 90/75 | 170/200 | 90/75 | 170/200 | 90/75 | D91 | 90/75 | 80/63 | 80/63 |

| 200/230 | 75/63 | 76 | 200/230 | 75/63 | D76 | 75/63 | 200/230 | 75/63 | 200/230 | 75/63 | D76 | 75/63 | 63/50 | 63/50 |

| 230/270 | 63/53 | 64 | 230/270 | 63/53 | D64 | 63/53 | 230/270 | 63/53 | 230/270 | 63/53 | D64 | 63/53 | 50/40 | 50/40 |

| 270/325 | 53/45 | 54 | 270/325 | 53/45 | D54 | 53/45 | 270/325 | 53/45 | 270/325 | 53/45 | D54 | 53/45 | ||

| 325/400 | 45/38 | 46 | 325/400 | 45/38 | D46 | 45/38 | 325/400 | 45/38 | 325/400 | 45/38 | D46 | 45/38 | ||

Abrasive Density (Abrasives with a high density are suitable for smaller grinding surfaces and thicker grain size while those with a lower density are suitable for large grinding surfaces and a finer grain size.)

| Diamond | Diamond weight in carat per cm3 abrasive volume | CBN | CBN weight in carat per cm3 abrasive volume |

| C50 | 2.2ct/cm3 | C50 | 2.2ct/cm3 |

| C75 | 3.3ct/cm3 | C75 | 3.3ct/cm3 |

| C100 | 4.4ct/cm3 | C100 | 4.4ct/cm3 |

| C125 | 5.5ct/cm3 | C125 | 5.5ct/cm3 |

| C150 | 6.6ct/cm3 | C150 | 6.6ct/cm3 |

If you can't provide the above information regarding grain size and density, the following information can also be useful for us to be able to recommend the most appropriate grinding wheel.

1. Work piece material, brand and hardness

2. Required surface roughness

3. Grinding machine model and supplier

4. Speed of grinding wheel (linear speed)

5. Grinding allowance

6. Work piece types

7. Whether online dressing is ok or not

8. Specification, manufacturer and mark of currently used grinding wheels

As a professional grinding wheel manufacturer and supplier, Hongtuo can offer a broad range of grinding wheels, including vitrified bond grinding wheels, resin bond grinding wheels, metal bond grinding wheels, electroplated diamond/CBN grinding wheels and more. For more details on our honing tools, grinding wheels, and other machining tools, please feel free to contact us.