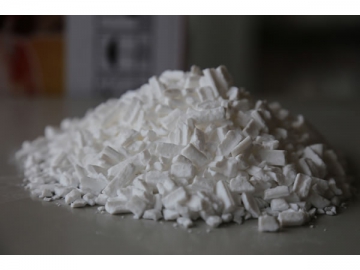

Precipitated Silica for Tires and Rubber Products

Precipitated Silica / Tire Silica / Industrial Silica

Precipitated silica is an essential raw material in environmentally friendly tires and rubber products, as it can improve both physical and chemical properties. Different types of silica are used according to the various formulations of rubber and tires in order to guarantee the expected performance.

As an active filler, silica replaces carbon black reinforcement traits on rubber products, which improves the mechanical properties, abrasion resistance, and thermal properties for rubber and oil resistant rubber products. It also improves the tensile strength, tear strength and the flexibility of rubber products and tires. Different rubber and tire compounds should use different silica types depending on the expected performance.

The 3XX series of high quality silica products is used for the reinforcement of rubber compounds, and offers a high reinforcement rate, clear transparency and excellent consistency.

There are three different forms: powder, micro-earl, and granular. The fluctuation value of the BET can also be controlled to be less than 10.

The ZJ-333 series of silica products has a low surface area, and a low rubber mixing viscosity, as well as an outstanding processing performance. For rubber products that have a low shore hardness, more silica is needed. This makes the ZJ-333 series ideal for highly dispersed car tires with specific requirements for rolling resistance on wet and dry roads, a longer service life and excellent handling properties. The high mount filling of this series of silica can improve the wet traction performance and winter road performance.

Application:

snow tires, special rubber, soft soles

| SiO2 | ≥ 98 |

| BET | 120-150 |

| Fe | ≤ 500 |

| pH | 6.0-7.5 |

The ZJ-335 series is a traditional precipitated silica used as a reinforcing filler in the rubber industry, designed to meet special needs between the 333 and 355 series. This particular series is available in a powder or granule form, and its main applications include car tire tread, and rubber compounds with requirements for hardness, wear, and powder consumption. By using a combination of bifunctional organosilanes, this silicate can achieve a low rolling resistance and high wet grip. In other applications, it can provide higher reinforcing properties, giving soles and other rubber products a high transparency. It is also used to make various adhesive systems.

Applications:

steel wires, wear resistant rubber products, and soles with specific requirements

| SiO2 | ≥ 98 |

| BET | 150-180 |

| Fe | ≤ 500 |

| pH | 6.0-7.5 |

The ZJ-355 series is a traditional precipitated silica used as a reinforcing filler in the rubber industry, covering nearly all aspects of the industry, and is available in either powders or granules. The main application for this series is a car tire tread, however, by using a combination with bifunctional organosilanes, it can achieve a very low rolling resistance, and a high wet grip. In other applications, the silica offers higher reinforcing properties, especially for making soles and other rubber products with a high transparency. This series is also widely used in different adhesive systems.

Applications:

radial tires, wear rubber, transparent soles

| SiO2 | ≥ 98 |

| BET | 160-190 |

| Fe | ≤ 500 |

| pH | 6.0-7.5 |

The ZJ-395 series is a traditional precipitated silica used as a reinforcing filler in the rubber industry, and can be used in nearly area of the rubber industry. This series is available in powders, particulate form and compacts, and is primarily used for high transparency and highly wear resistant soles, as well as engineering truck tire treads.

Application area:

engineering ties, high wear resistant rubber, high transparency soles

| SiO2 | ≥ 98 |

| BET | 181-210 |

| Fe | ≤ 500 |

| pH | 6.0-7.5 |

Storage

The precipitated silica should be stored in a ventilated, dry, cool place, avoiding direct sunlight, moisture and fire. Do not mix the silica with other materials. The storage temperature should be less than 40°C.

The warranty period is 12 months (from the date of manufacturing). After 12 months, a redetermination of the moisture content of the silicate product should be carried out. In order to use the product, all data must comply with requirements and health indicators. We do not recommend using the silicon dioxide product outside of the warranty period.

Packing

Standard packing includes small bags, paper bags, cartons, and flexible, intermediate bulk containers (FBICs) in order to meet specific customer requirements.

Other Applications