Precipitated Silica for Coatings

Coating Silica / Matting Agent Silica / Abrasion Resistant Silica

In coatings, silica is widely used as a dispersant, anti-depressant, and matting agent. It also improves abrasion resistance, glossiness and stability.

The main effects include:

1. Unsaturated polyesters: Avoid drop lets and wrinkles

2. Pigment: prevents precipitation, improves dye absorption, and improves the dispersion ability

3. Emulsion paint filler: improves thermal stability

4. Ink: matting agents, improved non-setting properties, dispersion, suspension and abrasion resistance

5. Printing ink: improves the printing effect, eliminating influence of non-dispersed ink penetration. Improves the wash ability, and the glossiness

The fluctuation value of the BET can be controlled to less than 10.

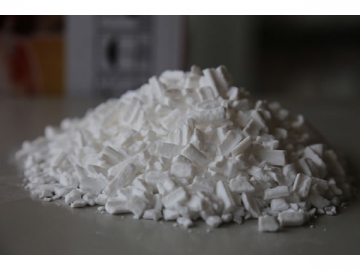

Specification

| Item | SiO2 (w/%) | DBP (ml/g) | Soluble salt solution (w/%) | Cu (ppm) | Fe (ppm) | Mn(ppm) | General use recommendation |

| ZJ-910 | ≧97.0 | 3.3-3.5 | ≦0.3 | ≦10 | ≦200 | ≦40 | mainly used as coating was a matting agent. It has superior performance, that meet the transparency and extinction needs. |

| ZJ-920 | ≧97.0 | 3.3-3.5 | ≦0.2 | ≦10 | ≦150 | ≦40 | can be applied not only in coating matting agent also can be used in the ink, it is possible to prevent and control the viscosity of the ink pigment sedimentation, increasing the sharpness of the colored ink. |

Storage

The silicon rubber silica should be stored in a ventilated, cool, dry place, away from direct sunlight, moisture and fire. It also should not be mixed with other materials. The storage temperature should be less than 40°C.

The warranty period is 12 months, from the date of manufacturing. After the 12 month period is up, a re-determination of the rubber silica product should be undertaken. In order to continue using the silica, all of its data must comply with industry health standards, though we do not recommend using the product outside of the warranty period, regardless.

Packing

Standard packaging includes small bags, paper bags, cartons and flexible intermediate bulk containers (FIBCs) in order to fully meet customer requirements.

The rubber silica product can also be packaged according to customer needs for material, form and size.

Applications