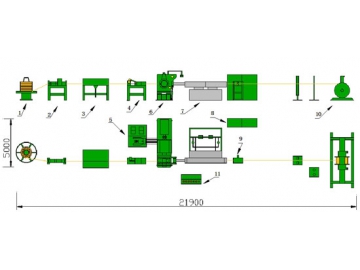

TJ400A Copper Bus Bar & Profile Line

Continuous Extrusion Machine for Alloy Copper Conductor

The TJ400A continuous rotary extrusion line for copper alloy wire adopts non-ferrous metal continuous rotary equipment as the main unit to produce alloy wires, such as the contact wires made of copper silver alloy and copper tin alloy.

Due to the adoption of continuous extrusion technology, the alloy wire production line is energy efficient and low investment due to the elimination of steps such as heating and annealing.

It also ensures uniform quality of the end products, as it can effectively avoid quality problems caused by uneven temperature during annealing while adopting traditional techniques. Thus, our range of continuous rotary extrusion line is able to produce consistent and stable quality copper alloy wires.

Additionally, the continuous rotary extrusion machine is effective in improving feedstock quality, as it can improve the plastic properties of metals and can also eliminate casting defects. During the continuous extrusion process, the metal is recrystallized, which ensures better constitution and refined crystal grains. For this reason, the mechanical and electrical properties of the feedstock can be enhanced to a great extent, which further ensures the end product quality.

| Main Unit: Continuous Extrusion Machine | |

| Model | TJ400A |

| Nominal Diameter of Extrusion Wheel | 400 mm |

| Rated Rotation Speed | 8 RPM |

| Power of Main Motor | 280kW |

| Feedstock: Alloy Copper Rod | |

| Diameter | Φ20mm |

| Diameter Tolerance | ±0.5mm |

| Yield Strength | |

| Copper Rod Payoff Unit | one set |

| Copper Rod Straightener | one set |

| Rod Material Scrubbing and Cleaning System | one set |

| Copper Rod Cutter | one set |

| Copper Continuous Extrusion Equipment | one set |

| Cooling and Oxidation Prevention System | one set |

| Meter Counter | one set |

| 1600 Gantry Type Take-up Machine | one set |

| Electrical Control System (with Touch Screen) | one set |

| Hydraulic and Lubricating System | one set |