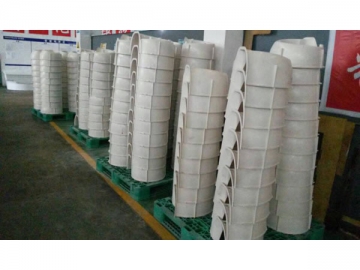

Fiberglass Products(Compression Molded Parts)

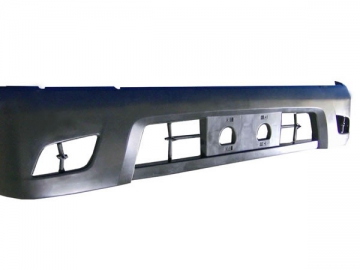

Fiberglass products, when manufactured correctly by compression molding, can offer many benefits including durability and excellent resistance to extreme temperatures and salty or humid conditions. Perhaps the biggest advantage to compression molded parts for car panel construction is that they are very easy to repair. Here we've listed more benefits of fiberglass products.

1. Economical

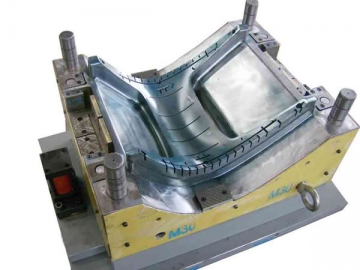

By choosing Haiyee as your compression molded products supplier, you save on cost. We take full advantage of our in-house mold development and construction capabilities to control tooling costs, molding precision, and production cycles.

For years, Haiyee has worked with many prominent suppliers in China to ensure we get only the best raw material at the lowest possible price. Therefore, we can cut down on production costs and pass more savings along to customers.

2. Time-Saving

By being involved in every step of fiberglass products production, from developing unique compression molds to compression molding fiberglass parts, we are able to control cycle time. Other manufacturers may send out their tooling jobs, but we don't. At Haiyee, we can fulfill rush orders as well small and large orders.

3. Dependable Company

Haiyee is a tool and die maker with rigorous work ethic. It is our mission to provide excellence in quality, so that our satisfied customers will use our services again. That in itself is the biggest compliment we could receive.

4. Premium Material

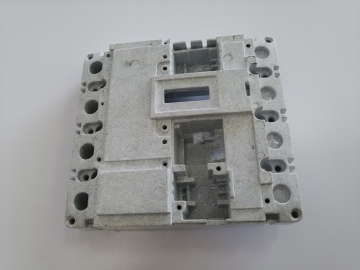

We use top of the line fiberglass-based plastics to make compression molded parts, including SMC and BMC materials.

SMC fiberglass is a thermosetting material, typically available in sheet form. SMC is composed of glass fiber (from specialized yarn), unsaturated polyester resin, low shrink additives, metal deactivators, and various textile auxiliaries. SMC fiberglass parts are pound for pound stronger than ordinary carbon steel, perform better in extreme temperatures, possess excellent thermal insulation properties, resist aging, and are poor electrical conductors which make them ideal for use in electrical appliances.

BMC fiberglass is comprised of the chopper fiber, unsaturated polyester resin, metal deactivator (peal bodyfiller), and various additives mixed in the form of a bulk pre-preg. BMC material is a thermosetting plastic that is more rugged than any thermoforming material to withstand stretching, bending and impact. BMC fiberglass parts have higher creep strength and are resistant to heating, aging, and electric arcs.

Hydraulic Press Tonnage

315T

800T

1500T

Mould heating manner: Oil/Electric/Steam

Hydraulic cylinder brand: HPS, Parker, etc.

Flow control valve: Delta

Note that our hydraulic press comes equipped with an oil heater, which applies heat to the fiberglass during compression molding. As new technology is released, we will continue to improve our molding quality by staying up to date with new equipment.

Compression Molded Fiberglass Products