Halogen-Free Heat Shrink Marker

Request a Quote

CYG-MT

Heat Shrinkable Identification Sleeve for Wire & Cable Management

- Material: Cross-linked modified polyolefin

- Shrink ratio: 2:1 / 3:1

- Compliant with UL224 and halogen-free standards

- Meets SAE-AMS-DTL-23053/5 and MIL-STD-202G requirements for label performance

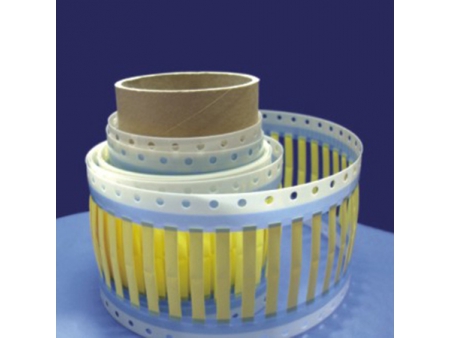

- Diverse packaging options to meet various customer needs

Applications

- Our halogen-free heat shrink marker sleeve is the ideal solution to meet the high-performance identification needs of manufacturers for cables, fixtures, and equipment management. This sleeve is made from cross-linked modified polyolefin material, which ensures high abrasion resistance and flame retardancy.

- It is widely used for circuit identification in electronic equipment across commercial, industrial, military, automotive, and aerospace sectors.

Features

- Compliant with UL224 and halogen-free standards

- Meets SAE-AMS-DTL-23053/5 and MIL-STD-202G requirements for label performance

- Diverse packaging options to meet various customer needs

- Compatible with standard dot matrix printers and thermal transfer printers

- Dual-sided printing for enhanced legibility

- Standard colors available: white and yellow, with custom color options

- Resistant to dirt, providing long-lasting identification

| Properties | Test Method | Typical Value |

| Tensile strength | SAE-AMS-DTL-23053 | ≥10.3MPA |

| Ultimate elongation | SAE-AMS-DTL-23053 | ≥200% |

| Low temperature flexibility (-25±1℃/4h) | SAE-AMS-DTL-23053-4.6.7 | -55℃, 4 hours, no cracking |

| Heat shock (-250±3℃/4h) | SAE-AMS-DTL-23053-4.6.8 | No dripping, no flowing, no cracking |

| Heat aging (175±2℃/168h) | SAE-AMS-DTL-23053-4.6.9 | No cracking |

| Tensile strength after aging (23±2℃) | SAE-AMS-DTL-23053-4.6.13&ASTMD638 | ≥6.9Mpa |

| Ultimate elongation after aging (23±2℃) | AE-AMS-DTL-23053-4.6.13&ASTMD638 | ≥100% |

| Color stability (23±2℃) | SAE-AMS-DTL-23053-4.6.15 | Pass |

| Dielectric strength (23±2℃) | SAE-AMS-DTL-23053-4.6.13&ASTMD2671 | ≥19.7kV/mm |

| Volume resistivity (23±2℃) | SAE-AMS-DTL-23053-4.6.13&ASTMD876, 500VDC,1MIN | ≥1014 Ω·cm |

| Flammability | SAE-AMS-DTL-23053-4.6.14&ASTMD2671&UL224 | VW-1 |

| Fluid resistance | AE-AMS-DTL-23053-4.6.11 | No visible damage |

| Printing durability | SAE AS81531 4.6.2 | After unidirectional rubbing for 50 times, the print is clearly visible |

| Printing solvent resistance | MIL-STD-202G METHOD 215K | Isopropyl alcohol (mineral spirits)10 rubs (x3) Terpene defluxer 10 rubs (x3) |

| Propylene glycol methyl ether (ethanolamine) 10 rubs (x3) |

Continuous Format Heat Shrink Marker (shrink ratio: 3:1), CYG-MT (3X)

| Size | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | |||

| Inside Diameter | Wall Thickness | Lay Flat Width | Total Thickness | Inside Diameter | ||

| Ø2.4 | ≥2.4 | 0.20±0.05 | 4.9±0.5 | 0.40±0.10 | ≤0.79 | 30 |

| Ø3.2 | ≥3.2 | 0.20±0.05 | 6.1±0.5 | 0.40±0.10 | ≤1.07 | 30 |

| Ø4.8 | ≥4.8 | 0.20±0.05 | 8.4±0.5 | 0.40±0.10 | ≤1.57 | 30 |

| Ø6.4 | ≥6.4 | 0.20±0.05 | 11.2±0.8 | 0.40±0.10 | ≤2.11 | 30 |

| Ø9.5 | ≥9.5 | 0.20±0.05 | 16.8±0.8 | 0.40±0.10 | ≤3.18 | 30 |

| Ø12.7 | ≥12.7 | 0.20±0.05 | 21.8±1.0 | 0.40±0.10 | ≤4.22 | 30 |

| Ø19.1 | ≥19.1 | 0.30±0.06 | 33.4±1.0 | 0.60±0.15 | ≤6.35 | 30 |

| Ø25.4 | ≥25.4 | 0.30±0.06 | 42.4±1.5 | 0.60±0.15 | ≤8.46 | 30 |

| Ø38.1 | ≥38.1 | 0.30±0.06 | 63.7±1.5 | 0.60±0.15 | ≤12.7 | 30 |

| Ø50.8 | ≥50.8 | 0.30±0.06 | 82.2±1.5 | 0.60±0.15 | ≤16.9 | 30 |

Continuous Format Heat Shrink Marker (shrink ratio: 2:1), CYG-MT (2X)

| Size | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | |||

| Inside Diameter | Wall Thickness | Lay Flat Width | Total Thickness | Inside Diameter | ||

| Ø2.4 | ≥2.4 | 0.15±0.05 | 5.1±0.4 | 0.30±0.10 | ≤1.17 | 30 |

| Ø3.2 | ≥3.2 | 0.15±0.05 | 6.7±0.4 | 0.30±0.10 | ≤1.58 | 30 |

| Ø4.8 | ≥4.8 | 0.15±0.05 | 9.1±0.5 | 0.30±0.10 | ≤2.36 | 30 |

| Ø6.4 | ≥6.4 | 0.15±0.05 | 11.5±0.5 | 0.30±0.10 | ≤3.18 | 30 |

| Ø9.5 | ≥9.5 | 0.20±0.05 | 16.5±0.5 | 0.40±0.10 | ≤4.75 | 30 |

| Ø12.7 | ≥12.7 | 0.20±0.05 | 21.7±0.5 | 0.40±0.10 | ≤6.35 | 30 |

| Ø19.1 | ≥19.1 | 0.20±0.05 | 2.2±0.8 | 0.40±0.10 | ≤9.53 | 30 |

| Ø25.4 | ≥25.4 | 0.20±0.05 | 42.0±0.8 | 0.40±0.10 | ≤12.7 | 30 |

| Ø38.1 | ≥38.1 | 0.20±0.05 | 62.3±0.8 | 0.40±0.10 | ≤19.05 | 30 |

| Ø50.8 | ≥50.8 | 0.25±0.05 | 82.0±0.8 | 0.50±0.10 | ≤25.4 | 30 |

Ladder Format Heat Shrink Marker (shrink ratio: 3:1), CYG-MT (3X)

| Size | As Supplied (mm) | After Recovery (mm) | Packaging (m/reel) | |||

| Inside Diameter | Wall Thickness | Lay Flat Width | Total Thickness | Inside Diameter | ||

| Ø2.4 | ≥2.4 | 0.20±0.05 | 4.9±0.5 | 0.40±0.10 | ≤0.79 | 2000 |

| Ø3.2 | ≥3.2 | 0.20±0.05 | 6.1±0.5 | 0.40±0.10 | ≤1.07 | 2000 |

| Ø4.8 | ≥4.8 | 0.20±0.05 | 8.4±0.5 | 0.40±0.10 | ≤1.57 | 2000 |

| Ø6.4 | ≥6.4 | 0.20±0.05 | 11.2±0.8 | 0.40±0.10 | ≤2.11 | 1500 |

| Ø9.5 | ≥9.5 | 0.20±0.05 | 16.8±0.8 | 0.40±0.10 | ≤3.18 | 1500 |

| Ø12.7 | ≥12.7 | 0.20±0.05 | 21.8±1.0 | 0.40±0.10 | ≤4.22 | 500 |

| Ø19.1 | ≥19.1 | 0.30±0.06 | 33.4±1.0 | 0.60±0.15 | ≤6.35 | 500 |

| Ø25.4 | ≥25.4 | 0.30±0.06 | 42.4±1.5 | 0.60±0.15 | ≤8.46 | 500 |

| Ø38.1 | ≥38.1 | 0.30±0.06 | 63.7±1.5 | 0.60±0.15 | ≤12.7 | 500 |

| Ø50.8 | ≥50.8 | 0.30±0.06 | 82.2±1.5 | 0.60±0.15 | ≤16.9 | 250 |

Ladder Format Heat Shrink Marker (shrink ratio: 2:1), CYG-MT (2X)

| Size | After Recovery (mm) | Packaging (m/reel) | ||||

| Inside Diameter | Wall Thickness | Lay Flat Width | Total Thickness | Inside Diameter | ||

| Ø2.4 | ≥2.4 | 0.15±0.05 | 5.1±0.4 | 0.30±0.10 | ≤1.17 | 2000 |

| Ø3.2 | ≥3.2 | 0.15±0.05 | 6.7±0.4 | 0.30±0.10 | ≤1.58 | 2000 |

| Ø4.8 | ≥4.8 | 0.15±0.05 | 9.1±0.5 | 0.30±0.10 | ≤2.36 | 2000 |

| Ø6.4 | ≥6.4 | 0.15±0.05 | 11.5±0.5 | 0.30±0.10 | ≤3.18 | 1500 |

| Ø9.5 | ≥9.5 | 0.20±0.05 | 16.5±0.5 | 0.40±0.10 | ≤4.75 | 1500 |

| Ø12.7 | ≥12.7 | 0.20±0.05 | 21.7±0.5 | 0.40±0.10 | ≤6.35 | 500 |

| Ø19.1 | ≥19.1 | 0.20±0.05 | 2.2±0.8 | 0.40±0.10 | ≤9.53 | 500 |

| Ø25.4 | ≥25.4 | 0.20±0.05 | 42.0±0.8 | 0.40±0.10 | ≤12.7 | 500 |

| Ø38.1 | ≥38.1 | 0.20±0.05 | 62.3±0.8 | 0.40±0.10 | ≤19.05 | 500 |

| Ø50.8 | ≥50.8 | 0.25±0.05 | 82.0±0.8 | 0.50±0.10 | ≤25.4 | 250 |