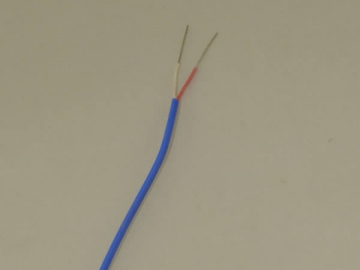

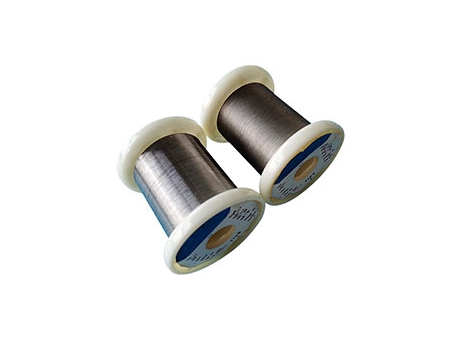

Thermocouple Bare Wire

Feature of Thermocouple Bare Wire

Type: K, E, J, T, N, etc.

Style: bright or oxidized

Application: forming two hot electrodes of thermocouple or compensating cable

Place of Origin: Jiangsu, China (Mainland)

Product size: 0.05mm - 10.0mm

Delivery time: 7-20 days which is according to quantity

Eco-friendly: Yes

MOQ: 1kg

Trade term: FOB, EXW, CIF, CFR

Payment term: T/T, Western Union, L/C

Certificate: ISO, CQC, ROHS

Sample production time: All types are available from stock

Advantage: high quality with high measuring accuracy, fast thermal response, high mechanical strength, long service lifetime, wide temp measuring range (-200℃~1300℃)

Classification of Thermocouple Bare Wire

Thermocouple level (high temperature level). This type of thermocouple wire is mainly suitable for thermocouple of type K, J, E, T, N and L and other high temperature measuring instruments, temperature sensors, etc.

Compensating wire level (low temperature level). This type of thermocouple wire is mainly suitable for compensating cable and extension wire of various thermocouples (like type S, R, B, K, E, J, T, N and L), heating cable, control cable, and so on.

Parameters of Thermocouple Bare Wire| Product Name | Type | Measurement Range (℃) |

| NiCr-NiSi | K | –200 ~ 1300 |

| NiCr-CuNi | E | –200 ~ 900 |

| Fe-CuNi | J | –40 ~ 750 |

| Cu-CuNi | T | –200 ~ 350 |

| NiCrSi-NiSi | N | –200 ~ 1300 |

| NiCr-AuFe0.07 | NiCr-AuFe0.07 | –270 ~ 0 |

| Thermocouple Type | Grade | Temperature Range (℃) | Allowable Deviation |

| type K and type N | I | –40 ~ 1100 | ±1.5℃ or ±0.4 % t |

| II | –40 ~ 1300 | ±2.5℃ or ±0.75 % t | |

| III | –200 ~ 40 | ±2.5℃ or ±1.5 % t | |

| type E | I | –40 ~ 1100 | ±1.5℃ or ±0.4 % t |

| II | –40 ~ 1300 | ±2.5℃ or ±0.75 % t | |

| III | –200 ~ 40 | ±2.5℃ or ±1.5 % t | |

| type J | I | –40 ~ 750 | ±1.5℃ or ±0.4 % t |

| II | –40 ~ 750 | ±2.5℃ or ±0.75 % t | |

| type T | I | –40 ~ 350 | ±0.5℃ or ± 0.4 % t |

| II | –40 ~ 350 | ±1.0℃ or ± 0.75 % t | |

| III | –200 ~ 40 | ±1.0℃ or ± 1.5 % t | |

| NiCr-AuFe0.07 | I | –270 ~ 0 | ±0.5℃ |

| II | ±1.0℃ |

| Anode | Cathode | Diameter (mm) | Maximum Temperature (℃) | |||

| Material | Code | Material | Code | Long-Time Using | Short-Time Using | |

| NiCr10 (Chromel) | KP | NiSi3 (Alumel) | KN | Φ0.3 | 700 | 800 |

| Φ0.5 | 800 | 900 | ||||

| Φ0.8 Φ1.0 | 900 | 1000 | ||||

| Φ1.2 Φ1.6 | 1000 | 1100 | ||||

| Φ2.0 Φ2.5 | 1100 | 1200 | ||||

| NiCr14.2Si | NP | NiSi4 | NN | Φ3.2 | 1200 | 1300 |

| NiCr10 (Chromel) | EP | CuNi45 (Copel) | EN | Φ0.3 Φ0.5 | 350 | 450 |

| Φ0.8 Φ1.0 Φ1.2 | 450 | 550 | ||||

| Φ1.6 Φ2.0 | 550 | 650 | ||||

| Φ2.5 | 650 | 750 | ||||

| Φ3.2 | 750 | 900 | ||||

| Fe(Iron) | JP | CuNi45 (Copel) | JN | Φ0.3 Φ0.5 | 300 | 400 |

| Φ0.8 Φ1.0 Φ1.2 | 400 | 500 | ||||

| Φ1.6 Φ2.0 | 500 | 600 | ||||

| Φ2.5 Φ3.2 | 600 | 750 | ||||

| Cu (Copper) | TP | CuNi45 (Copel) | TN | Φ0.2 Φ0.3 | 150 | 200 |

| Φ0.5 Φ0.8 | 200 | 250 | ||||

| Φ1.0 Φ1.2 | 250 | 300 | ||||

| Φ1.6 Φ2.0 | 300 | 350 | ||||