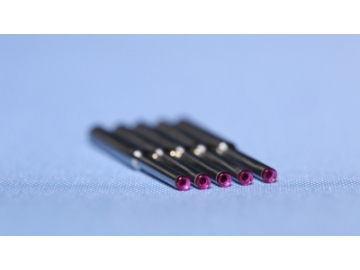

Stainless Steel Nozzle with Ruby Tip

Description

The stainless steel nozzle with a ruby tip is the key wire guiding parts that are suitable for high speed winding of fine coils and ultra-thin enameled wire, as well as other conditions with strict requirements. During operation, the wire passes through the nozzle, and a winding process is carried out under nozzle guidance.

The stainless steel nozzle with ruby tip is the key component to ensuring the quality of the winding finished product carried out by the winding machine. It is often used for product production in electrical industries, including transformers, inductors, voice coils and more.

MaterialThe stainless steel nozzle with a ruby tip is made of high quality stainless steel with a certain hardness. The wire inlet and outlet are embossed with finely machined crystals with a hardness range of 1800 to 2200 Vickers.

This nozzle combines the strength of stainless steel with the ultra-high hardness of ruby. Compared to a tungsten carbide nozzle, it has an excellent wear resistance and will not easily break. Under the same application environment, the stainless steel nozzle with a ruby tip has double the service life than that of the tungsten carbide nozzle.

Processing

After grinding and polishing treatment, the roughness of the inner hole, outer diameter and the R part can be up to Ra 0.025, thus minimizing damage to the enameled wire. The hole diameter of the wire outlet can be processed to as low as 0.3mm.

Optional specification

| Specification | Total length L | Minor diameter L1 | Major diameter D | Minor diameter D1 | Hole diameter of the wire outlet d1 | Hole diameter of the wire inlet d2 | |

| TB0403-2008-1505 | 15 | 5 | 2 | 0.8 | 0.3 | 0.4 | |

| TB0403-2008-3007 | 30 | 7 | 2 | 0.8 | 0.3 | 0.4 | |

| TB0403-2508-1505 | 15 | 5 | 2.5 | 0.8 | 0.3 | 0.4 | |

| TB0403-2010-3510 | 35 | 10 | 2 | 1 | 0.3 | 0.4 | |

| TB0403-3010-1505 | 15 | 5 | 3 | 1 | 0.3 | 0.4 | |

| TB0403-3008-2504 | 25 | 4 | 3 | 0.8 | 0.3 | 0.4 | |

| TB0403-3008-3007 | 30 | 7 | 3 | 0.8 | 0.3 | 0.4 | |

| TB0403-3010-3015 | 30 | 15 | 3 | 1 | 0.3 | 0.4 | |

| TB0403-3010-4510 | 45 | 10 | 3 | 1 | 0.3 | 0.4 | |

| TB0605-3010-3005 | 30 | 5 | 3 | 1 | 0.5 | 0.6 | |

| TB0605-3012-3010 | 30 | 10 | 3 | 1.2 | 0.5 | 0.6 | |

| TB0605-3015-1505 | 15 | 5 | 3 | 1.5 | 0.5 | 0.6 | |

| TB0605-4020-3010 | 30 | 10 | 4 | 2 | 0.5 | 0.6 | |

| TB0505-3015-3015 | 30 | 15 | 3 | 1.5 | 0.5 | 0.5 | |

| TB0806-3015-3010 | 30 | 15 | 3 | 1.5 | 0.6 | 0.8 | |

| TB0806-2018-3507 | 35 | 7 | 2 | 1.8 | 0.6 | 0.8 | |

| TB0806-3015-3008 | 30 | 8 | 3 | 1.5 | 0.6 | 0.8 | |

| TB1008-4020-1505 | 15 | 5 | 4 | 2 | 0.8 | 1 | |

| TB0808-3000-4500 | 45 | * | 3 | * | 0.8 | 0.8 | |

| TB0808-3015-1409P | 14 | 9 | 3 | 1.5 | 0.8 | 0.8 |

Package