Spring Starter

Introduction

Spring starter uses disc spring as the energy storage medium. The spring is compressed manually and then energy is released quickly to diesel engine flywheel to start the engine. There is no energy consumption or pollution emission during this process.

Mounted on a diesel engine, the spring starter does not require storage battery, compressed air tank, hydraulic actuator, control value, cable or pipelines. It uses superior solid lubricating anti-wear agents. Hence, no spark or radiation appears during working. This makes the spring starter suitable for use in occasions sensitive to sparks or difficult to implement equipment maintenance.

Application

1. General Industrial Uses

The spring starter can serve as a backup starting system when installed in the land or marine generator set, mining machinery, construction machinery, as well as agricultural drainage and irrigation machinery.

2. Special Environment

The spring starter can also serve in coal mine, oil field, or chemical plant.

3. Emergency Conditions

The spring starter can be used in the fire fighting equipment, rescue boat, as well as drainage and power supply equipment. It is also used for some military purposes.

Features

1. Our spring starter is able to meet the starting needs of the diesel engine with the displacement of 3-19 liters. It can adapt to different working environments, but in severe cold regions, an auxiliary starting device is required.

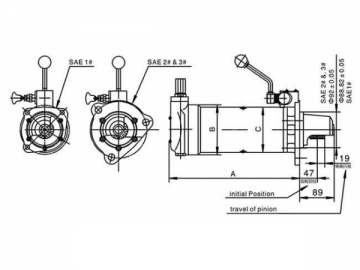

2. The installation of spring starter conforms to SAE standard.

3. The winding direction can be adjusted to attain the optimal winding angle.

Outline Drawing

2. Travel of Pinion

Comparison of Spring Starter and Air Starter

The structure and installation of spring starter is much simpler than that of air starter. Also, compressed air tank is not required.

| DL Spring Starter | HD | HDP | SHD | HDP-2 | HDC | |

| Heavy Duty | Heavier Type | Extra Heavy Duty | Heavier Type 2 | Heavy Duty Inversion | ||

| 1100 | 2100 | 3100 | 4100 | 5200 | ||

| Mounting flange | SAE# | 1,2&3 | 1,2&3 | 1,2&3 | 1,2&3 | 1,2&3 |

| Engine displacement | L/cylinder & Max. number of cylinders | 1.4&6 | 1.7&6 | 2.5&6 | 2.1&6 | 1.4&6 |

| 1.4&8 | 2.0&8 | 1.7&8 | ||||

| Driving torque | Nm | 126 | 126 | 167 | 126 | 126 |

| Max. winding torque | Nm | 100 | 100 | 100 | 100 | 100 |

| Winding turns | / | 2 8 | 2 11 | 2 15 | 2 13 | 2 8 |

| Length A | mm | 288 | 332 | 368 | 368 | 288 |

| Diameter B | mm | 130 | 130 | 143 | 130 | 130 |

| Diameter C | mm | 117 | 117 | 133 | 117 | 117 |

Note: The spring starter is generally equipped with an interlocking device for misoperation prevention.

Typical Application

| Picture No. | 1 | 2 | 3 | 4 |

| Engine Model | Cummins B, C, L | Weichai 226B,WP6/4 | Huachai F8L513/413, 1015 | Yuchai YC6T/B, 4D/F |

| Starter Series | 1100,2100,4100 | 1100,2100 | 2100,4100, 3100 | 1100,2100,3100 |

| SAE# | 1,2,3 | 1 | 1,2,3 | 1,2,3 |

| Flywheel Housing | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore |

| Picture No. | 5 | 6 | 7 | 8 |

| Engine Model | Cummins NT | Weichai WD10, WD12 | TBD234 V6, V8, V12 | Hangzhou WD615/415 |

| Starter Series | 3100 | 2100,4100 | 2100,4100, | 2100,4100 |

| SAE# | 3 | 1 | 1 | 1 |

| Flywheel Housing | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore |

| Picture No. | 9 | 10 | 11 | 12 |

| Engine Model | Shangchai 6135, G128 | VOLVO D7A | CAT C4.4 | Changchai 380-485 |

| Starter Series | 2100,4100 | 1100 | 1100,2100 | 5200 |

| SAE# | 1 | 1 | 1 | 1 |

| Flywheel Housing | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore | 1 or 2 Starter Bore |

Note:

1. The orientation of the starter spindle head can be adjusted according to the type of engine.

2. The drive gear number of spring starter can vary with the flywheel ring gear of the engine to be started.

3. According to the single or dual bore design of engine flywheel housing, the spring starter can be used as a backup for electric motor. It can also serve as a primary or secondary starting source during emergency.