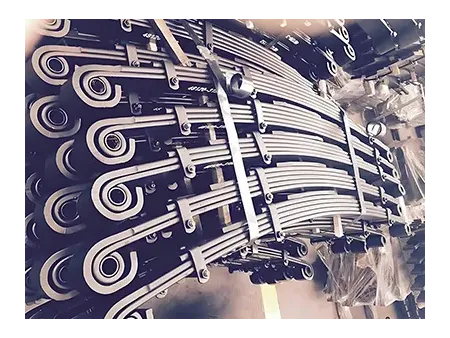

Leaf Spring (Steel Parabolic Spring)

Diversified leaf spring suspensions are available (Germany / American / York suspension).

- Single point suspension, top piece suspension

- 2-axle suspension

- 3-axle suspension

- 4-axle suspension

- Air bag suspension

Monthly capacity: 4,000 sets suspension is available for semi-trailer.

Following axles with 8 holes and 10 holes are waiting for you to choose:

- 12 ton capacity axle

- 13 ton capacity axle

- 14 ton capacity axle

- 16 ton capacity axle

With the effort of 50 technicians, SUYU develops diversified axles with different sizes and types that have various applications. Meanwhile, owing to our strict quality control system, the product enjoys high quality and a good reputation all over the world.

Basically a parabolic spring is a spring that consists of two or more leaves. The leaves touch only in the center, where they are fixed to the axle and at the outer ends, where they are fixed to the vehicle. In between those two points the leaves do not touch each other as they do with conventional leaf springs.

Each leaf represents a complete spring in its self and will act as such. To enable the leaf spring is tapered, from the center (thick) to the outer ends (thin). This tapering is parabolic, it means that every centimeter (or inch) the thickness of the leaf decreases in an amount that relates to the square function of it's length.

This may sound complicated but in fact it is very simple. Every single leaf will have, more or less, the shape of a complete multi leaf spring and thus it's capable to cope with the same forces. This means that the ideal parabolic spring could have only one leaf, however, this type of "mono leaf" spring will have very limited articulation/weight ratio due to high internal stresses so a 2 or 3 leaf parabolic spring can divide the stresses more evenly across the other leaves and thus more axle movement is possible. That is why we designed 2 and 3 leaf springs. An other reason to increase the number of leaves on a parabolic spring is to increase the rate (load capacity). Because every leaf is one spring we can add or take out leaves without compromising the strength of the leaf it self. So for example we have a 3 leaf rear spring and we add one similar leaf the rate will go up for about 30% which means that the load capacity increases by /- 30% (depending on the shackle effect)