Automatic Steel Pipe Galvanizing Line

GONGDA is one of the famous plating equipment suppliers in China. Our automatic steel pipe galvanizing line features high automation degree, PLC control system, and fluted disc galvanizing method. Variable frequency motor is used for controlling the galvanizing time. Comparing with other hot-dip galvanizing solutions, this galvanizing equipment is more flexible in terms of processing time. The steel pipe with a 1/2"~6"drift diameter can be automatically dipped into the galvanizing kettle. Specifically,two or four pipes with 1/2"~2" diameters could be galvanized by our automatic steel pipe galvanizing line each time, while for those that are 2"~6" in diameter can be processed one piece a time. The inner wall of the pipe is blown by steam, while the outside will be blown by compressed air.

Parameter of automatic steel pipe galvanizing line

- Steel pipe dimension:

Drift diameter: 1/2"~6"

Wall thickness: 1.5mm~3.5mm

Pipe length: 6~8m - Galvanizing method:

Two or four pieces per time (Pipe diameter = 1/2"~2")

One piece per time (Pipe diameter > 2") - Blowing method:

Inside: superheated steam (275℃)

Outside: compressed air - Steam requirements:

Pressure: 1.25MPa (working pressure ≥ 1.0MPa)

Consumption: 2 tons/hour

Temperature: 275℃

Quality standard: GB3091-2008

Production capacity: 30,000~60,000 tons/year

Energy: natural gas/ liquefied petroleum gas/ electricity

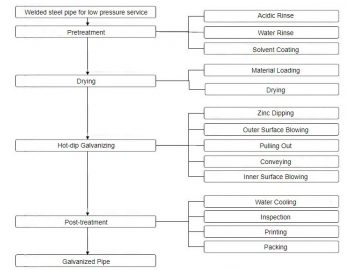

Process flow of automatic steel pipe galvanizing line

Main equipment of our automatic steel pipe galvanizing line

Pre-treatment bath, chain type drying furnace, galvanizing furnace, galvanizing unit, big pulling-out mechanism (big magnetic roller, two pipes each time), small pulling-out mechanism (small magnetic roller), blowing equipment, double line pipe conveying device, swinging girder, water cooling bath, lifting mechanism for water cooling bath, printing machine, filter bag for dust removing, sewage neutralizing equipment, acid fume scrubber, flux regeneration equipment (by solvent)