Online Crusher for Plastic Thermoforming Machine

Request a Quote

Crushing and recycling of waste plastic sheets during plastic cup manufacturing

The online crusher automatically processes waste plastic sheets produced during the thermoforming of plastic cups. This system ensures immediate recycling, reducing waste accumulation and enhancing overall production efficiency by synchronizing with the main plastic cup manufacturing machine and diverting waste for crushing and reuse.

Technical Specifications

| Model | |

| Max. inlet width | 800/900/1000mm (optional) |

| Inlet type | Single inlet/double inlet |

| Main motor power | 15kW×4 |

| Main motor speed | 1480rpm |

| Motor of conveyor transfer | 5.5kW |

| Blower speed | 2800rpm |

| Traction motor power | 1.5kW |

| Traction speed | 5-40m/min |

| Rotating blades | 6 |

| Chamber size | 1000×250mm |

| Max. crushing capacity | 250-550kg/hr |

| Material of blades | DC53 |

| Mesh size | 8-12mm |

| Machine dimensions (L×W×H) | 1800×1200×1500mm |

| Machine weight | 1800kg |

Mechanical Components

-

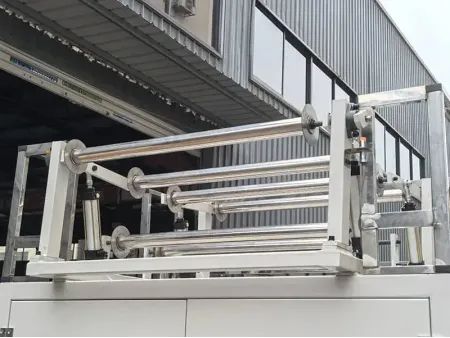

- The dragger spindle is finely processed using high-strength seamless tubes, featuring hard chrome plating for an elegant, rust-resistant appearance. It meets environmental standards and is built to be sturdy and durable.

- The machine body is made from high-quality metal plates, offering both elegance and durability.

Dragger part -

- The cutter is made from DC53 mold steel, known for its high hardness and strong wear resistance. It can be re-sharpened and is secured with high-stretch screws, ensuring stability and the ability to break down a variety of soft and hard materials.

- The crushing machine body uses high-strength steel plates, precision-finished by machine tools and integrated through welding, ensuring long-lasting durability and resistance to deformation.

- The tool rest features a hollow-type design, offering stable operation, low windage, and enhanced durability.

- The belt-driven system utilizes mature technology, providing stable operation and minimal maintenance.

- Material thickness range for crushing is 0.5-3mm. For thicker materials, please specify when placing an order.

Crusher part -

- The blower housing and blades are made from high-quality metal plates, ensuring environmental hygiene, a sleek appearance, and durability.

Blower part -

- We use high-density soundproof cotton to maintain noise levels below 50dB during operation.

Soundproof design -

- We offer stock machines for prompt shipment.

Finished machine