Wire and Cable Extrusion Line

30mm-150mm Wire Extruder Production Line

Application

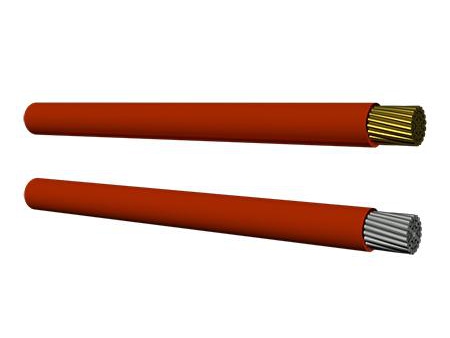

The wire and cable extrusion line is primarily used for wire and cable insulation using PVC, LDPE, Nylon and TPU. It can also be equipped with a triple co-extrusion crosshead and double layering system.

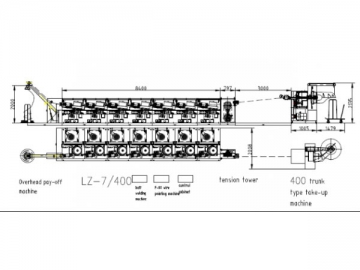

Production Line Consists

Pay off, main cabinet, fixed trough, movable trough, accumulator, traction device, take-up, spark tester.

Optional Parts

Active pay off, pre-heater, power machine, diameter-testing laser gauge, LSZH screw, single and dual bobbin take-up, coiling and wrapping machine.

Features

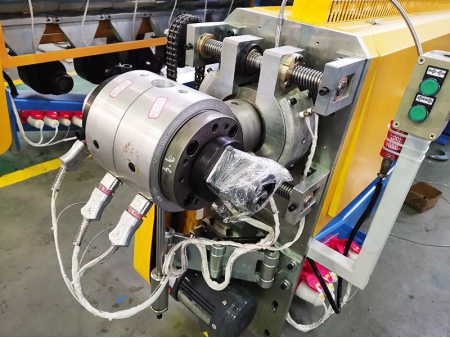

The extrusion machine can achieve a concentricity of the finished wire products of more than 90% with high precision. All of this is possible with the user-friendly interface and automated operation.

| Type and Designation | Screw Parameters | Extrusion Capacity(kg/h) | Power(kw) | Finished Wire Dia.(mm) | |||||

| Dia. (mm) | L/D Ratio | Rotation Speed (r/min) | PVC | LDPE | PP | Main Motor Power | Total Power | ||

| FJX-30 | Φ30 | 25:1 | 20-110 | 25 | 16 | 13 | 5.5 | 21 | 0.2-1 |

| FJX-40 | Φ40 | 25:1 | 20-110 | 40 | 20 | 17 | 7.5 | 24 | 0.4-3 |

| FJX-50 | Φ50 | 25:1 | 20-110 | 80 | 40 | 34 | 11 | 28 | 0.8-5 |

| FJX-60 | Φ60 | 25:1 | 15-110 | 100 | 53 | 41 | 18.5 | 42 | 1-8 |

| FJX-70 | Φ70 | 25:1 | 15-110 | 130 | 86 | 68 | 22-37 | 50 | 2-12 |

| FJX-80 | Φ80 | 25:1 | 10-90 | 200 | 122 | 96 | 30-55 | 65 | 3-25 |

| FJX-90 | Φ90 | 25:1 | 10-80 | 240 | 133 | 124 | 37-75 | 75-113 | 5-35 |

| FJX-100 | Φ100 | 25:1 | 85 | 280 | 190 | 150 | 75-90 | 134-149 | 10-60 |

| FJX-120 | Φ120 | 25:1 | 80 | 380 | 260 | 200 | 90-132 | 176-208 | 12-70 |

| FJX-150 | Φ150 | 25:1 | 60 | 650 | 400 | 350 | 110-160 | 205-255 | 15-80 |

70mm-200mm Cable Extruder Production Line

Usage

PVC, LDPE, Nylon, and TPU insulation.

Production Line Consist

Pay off, main machine, main cabinet, fixed trough, traction, take-up.

Optional Parts

Caterpillar, sparkling machine, diameter-testing laser gauge, LSZH screw, gantry type take-up and pay off, end-shaft type take-up and pay off.

| Model | Screw Parameters | Extrusion capacity(kg/h) | Power(kw) | Pay-off wire dia.(mm) | Finished wire dia.(mm) | ||

| Dia. (mm) | L/D Ratio | Rotation Speed (r/min) | Extrusion Capacity | Main Motor Power | Pay-off wire dia.(mm) | Finished Wire Dia.(mm) | |

| FJX-70 Extrusion | Φ70 | 25:1 | 100 | 130 | 30 | 3-15 | 4-30 |

| FJX-80 Extrusion | Φ80 | 25:1 | 95 | 180 | 75 | 3-20 | 4-40 |

| FJX-90 Extrusion | Φ90 | 25:1 | 90 | 280 | 90 | 3-35 | 4-45 |

| FJX-100 Extrusion | Φ100 | 25:1 | 85 | 330 | 110 | 4-50 | 5-60 |

| FJX-120 Extrusion | Φ120 | 25:1 | 80 | 420 | 132 | 8-70 | 8-80 |

| FJX-150 Extrusion | Φ150 | 25:1 | 70 | 780 | 160 | 8-100 | 15-120 |

| FJX-200 Extrusion | Φ200 | 25:1 | 60 | 1000 | 250 | 30-140 | 35-145 |