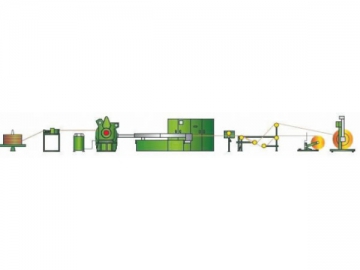

Copper Continuous Extrusion Machine

Usage

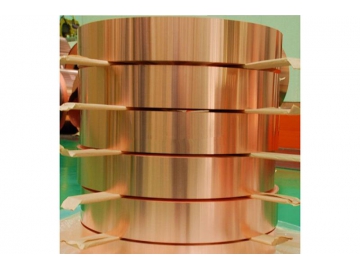

The continuous extrusion machine is designed for the production of flat copper wire, copper bars and other conductor products.

Main Parts

(1) Winding machine

Function: Rotates at high speed to release the coiled wire after it is produced.

Material: High quality steel.

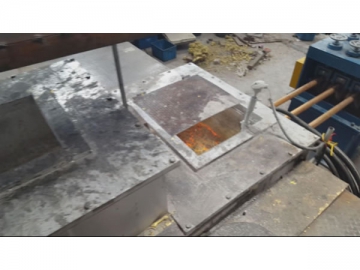

(2) Rod Straightener and Cutter Unit

Function: Straightens and cuts the feeding rod. The base is a four door cabinet designed for holding the tooling and dies.

Material: High quality alloy steel.

Feature: Applies the pulling force of the extruder.

| Part | Model or Material | Brand |

| Base | 30mm Thickness Q345A Steel | Self made |

| Stand | 100mm Thickness Q345A Steel | Self made |

| Main Shaft | 42CrMo forging & fault detection | Self made |

| Shoe Standing | 40Cr forging steel | Self made |

| Gear Box | TX Series Planetary | Tailong, Jiangsu |

| Main Motor | Z4 Series DC | Nanyang, Wuxi |

| Coupling | 45# steel thermal refining | Self made |

| Compress Cylinder | 40Cr Steel refining | Self made |

(4) Cooling and Anti-Oxidation System

Function: Cooling for the tooling and products is applied separately. The system consists of 1 product cooling sink, 1 product cooling tank, and 1 tooling cooling tank.

(5) Drying, Measurement and Alarm system

Function:

Drying: Wipe drying and compressed air drying to remove water from the product surface to prevent product oxidization.

Length Measurement: Set to any expected length and any alteration in operation will set off an alarm.

(6) Take-Up Machine

Function: It applies both a tension and speed control mode. The winding tension and pitch can be adjusted and digitally displayed. The traverse direction can be changed both automatically and manually.

(7) Electric Control System

Configuration| Part | Model or Material | Brand |

| DC Drive | SSD590 | Parker |

| PLC | S7-200 Series | SIEMENS |

| Electrical Parts | SCHNEIDER |

| Model | |||||||

| Extrusion wheel dia.(mm) | 250 | 300 | 300 | 350 | 400 | 500 | 630 |

| Max. width (mm) | 14 | 40 | 50 | 80 | 170 | 240 | 320 |

| Section area (mm2) | 5-50 | 10-200 | 10-250 | 600 | 2000 | 3800 | 6400 |

| Productivity (kg/h) | 160 | 480 | 620 | 860 | 1300 | 2000 | |