Hydraulic Wire Saw

Valued Clients:

Please note, all product information has been updated, to view the latest information please click on the Navigation - Product. Thank you!

Developed from 10 years of practice experience in concrete cutting industry, our TD type hydraulic wire saw offers an efficient, safe and economical solution for wire sawing of concrete and reinforced concrete in bridge, tunnel, supporting beam and other structure cutting projects. The concrete wire saw can be powered by our TD-18.5, TD-22 or TD-25 hydraulic power unit. It is often used with wall saw to be more powerful and bear up the toughest operating conditions. It is now the indispensable cutting equipment in removal of large concrete constructions.

1. The diamond wire saw employs linear cutting which make cut section more clean and trim. It can greatly improve speed to shorten construction period and further reduce labor cost, enhance bid superiority and enlarge construction scale.

2. It comes with overload protection function which can considerably improve safety in construction. With strong power, high cutting capacity and productivity, it becomes the preferred cutting equipment in construction removal and demolition projects.

3. High safety, reliability and stability of hydraulic system dramatically reduce cost in loss.

4. The hydraulic wire saw is one of non-destructive construction equipment which can maximally maintain the stability and safety of existing structure. This enables it to be a perfect replacement for traditional ways.

5. According to actual needs and purposes, we offer two types of hydraulic wire saws that are manufactured from state of the art imported accessories and German technologies. Imported accessories make saw head more compact in size.

The wire saw is designed to cut and remove super thick and heavy reinforced concrete and irregular concrete such as bridge cap beam, box beam and support beam, pier, foundation, underwater concrete, etc. Partial demolition can only be completed by wire saw which offers high flexibility and capability of cutting in any direction.

Generally, the hydraulic wire saw is widely used in the construction projects of demolition companies for reconstruction and reinforcement purposes. As a special cutting tool, it makes reinforced concrete removal easier, safer and more efficient.

1. State of the Art Structure

The hydraulic wire sawing equipment comes with state of the art structure. It is designed with double motors and automatic take-up.

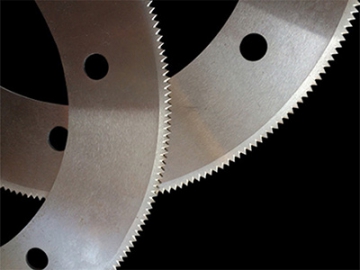

Roller Track

Roller Track Pulley System

Pulley System Machine Frame

Machine Frame

1) Roller Track

The roller tracks are made of aviation aluminum which ensures light weight and high strength.

Guide pulley, take-up pulley and drive pulley are all featured with simple structure. They are engineered from high intensity aluminum alloy to reduce weight.3) Machine Frame

Frame of the hydraulic wire saw is designed with no redundant structure. It is simplified to the maximum extent while maintaining high strength.

3. Easy Installation

The wire saw employs split installation method. It can be divided into three parts.Splitinstallation can reduce the installation weight of each part, thus enabling the machine to be installed by one person.

a. First step: Only installing foot and tracks

b. Second step: Installing drive wheel

c. Third step: Installing pulley system

A worker is installing foot and saw tracks

A worker is installing foot and saw tracks  Second step: Installing drive wheel

Second step: Installing drive wheel Third step: Installing pulley system

Third step: Installing pulley system

| No. | Name | Number | Remark |

| 1 | TD Hydraulic power unit | 1 | Imported |

| 2 | Oil hose | 5 | Imported |

| 3 | Water hose | 1 | Specialized |

| 4 | Clamping plate | 2 | Fixing the frame |

| 5 | Waterproof plug | 2 | |

| 6 | Column | 1 | |

| 7 | Wire saw frame | 1 | Including travel and drive wheel, frame and saw track |