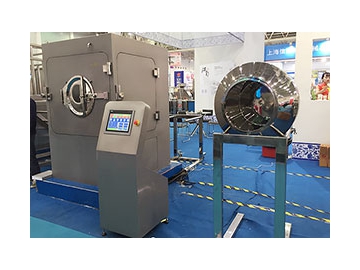

High Efficiency Tablet Coating Machine

With beautiful appearance, high efficiency, low power consumption and other advantages, the high efficiency tablet coating machine can make organic film, water soluble film and sugar coating for various tablets, pills, candies, etc. Widely used in pharmacy, food, biology and other areas, this machine has been exported to Southeast Asia, Australia, Europe, Middle East, South America and other regions.

The tablet core keeps doing complex motion inside the clean and sealed rotation drum. After mixed by the thermostatic mixing drum, the coating medium is sprayed over the tablet core through the spray gun. Clean hot air supplied by the hot air cabinet passes through the tablet core and is later discharged from the ventilation door, which makes coating medium dries quickly and forms a solid, dense and smooth film on surface of the tablet core. The whole process is completed under the control of PLC.

The high efficiency tablet coating machine is equipped with automatic feeding and discharging device, which is convenient and efficient and prevents cross contamination. Under the action of streamline guide plate stirrer, the tablet core moves smoothly and frequently, which eliminates the phenomena of falling from high places and collision, solves the problem of fragments and cracked edges and improves yield. The narrow upper surface of the guide plate prevents auxiliary materials adhering on it, which saves auxiliary materials and improves product quality.

Specifications| Model | ||||||||||

| Load Capacity (L) | 1000 | 600 | 400 | 260 | 150 | 80 | 40 | 10 | ||

| Coating Pan Speed (rpm) | 0-12 | 1-12 | 1-13 | 1-16 | 1-16 | 1-19 | 1-21 | 1-25 | ||

| Main Motor Power (kW) | 7.5 | 5.5 | 3 | 2.2 | 2.2 | 1.5 | 1.1 | 0.55 | ||

| Coating Pan Diameter (mm) | 1580 | 1580mm | 1580mm | 1360mm | 1200mm | $930mm | 750mm | 500mm | ||

| Motor Power of Air Exhaust Cabinet (kW) | 22 | 11 | 7.5 | 5.5 | 5.5 | 3 | 2.2 | 0.75 | ||

| Air Exhaust Flow (m3/h) | 20000 | 15450 | 10000 | 7419 | 7419 | 5268 | 3517 | 1285 | ||

| Motor Power of Hot Air Cabinet | 7.5 | 5.5 | 3 | 2.2 | 1.5 | 1.1 | 0.75 | 0.37 | ||

| Air Flow of Hot Air Cabinet (m3/h) | 10000 | 7419 | 5200 | 3517 | 2356 | 1685 | 1285 | 816 | ||

| Machine Weight (kg) | 4000 | 2800 | 1562 | 1300 | 1020 | 684 | 500 | 200 | ||

| Clean Air | Pressure (Mpa) | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | |

| Air Consumption (m3/min) | 3.5 | 2 | 1.5 | 1.2 | 1 | 0.4 | 0.4 | 0.3 | ||

| Dimensions (mm) | Main Machine | 2500×3100×2800 | 2000×2277×2660 | 2000×167×2660 | 1730×1440X2470 | 1570X1280×2250 | 1210×10000X1900 | 1000×800×1900 | 900×620×1800 | |

| Hot Air Cabinet | 1700×1200×2600 | 1600×1100×2350 | 1000×x900×2300 | 1000x900×2300 | 1000x900×2300 | 900×800×22050 | 900×800×2050 | 800×650×1600 | ||

| Air Exhaust Cabinet | 3000×1115×2400 | 1050×1000×2470 | 1050×1050×233 | 1050×1060×2300 | 950×950×2245 | 900×820×2130 | 820×720×1750 | |||

| Steam Heating Power (kW) | 40 | 29 | 18 | 14 | 14 | 10 | 9 | |||

| Electric Heating Power (kW) | 120 | 79 | 61 | 48 | 42 | 30 | 24 | 12 | ||

Easy to operate, the imported spray gun is able to work under the shooting pressure of 0.29-0.39Mpa and atomizing pressure of 0.4-0.5Mpa, which prevents dripping and clogging. With adjustable flow, angle and fan, the spray gun yields uniform atomization and large spray surface.

A special mechanical device is mounted inside the high efficiency tablet coating machine, which can be controlled to coat small amounts of tablets without wasting auxiliary materials. In addition, an automatic cleaning system, including a high-pressure spray gun inside the coating pan and cleaning nozzles in exhaust outlet and air inlet, is optional. The spray gun can rotate 180 degree and the cleaning nozzles are able to rotate automatically in all directions, making cleaning more convenient and complete.

Major components of this high efficiency tablet coating machine are described below.

-

Filter-cartridge exhaust cabinet

Integral to tablet coating machines, the filter-cartridge exhaust cabinet plays a crucial role in maintaining a clean working environment. This cabinet excels in air extraction, efficiently removing air and dust from the main drum, and ensuring a consistently negative pressure in the operational area. It features an advanced filter-cartridge system, which employs compressed air pulses for effective dust removal. The filtration efficiency of this system is impressive, achieving F9 grade standards and offering an upgrade option to H13 grade upon customer request.

An outstanding feature of this exhaust cabinet is its vibration-damping mechanism, guaranteeing stable and quiet operation. Additionally, the exhaust port is designed with a backflow prevention device. This feature becomes particularly beneficial when the machine is not in operation, as it seals the exhaust port to prevent any reverse flow of waste gases into the ductwork. Compact yet robust, this exhaust cabinet is crucial for ensuring clean and safe conditions in industrial settings. -

Agitating and holding tank (Electric-Heating)

The electric-heating agitating and holding tank presents a comprehensive solution to ensure uniform mixing and precise temperature control in a wide range of industrial processes. Designed with a pneumatic agitator, it uses compressed air for power, enabling smooth and adjustable mixing speeds. This tank's distinctive design guarantees consistent stirring, ensuring a uniformly mixed medium.

The agitating and holding tank can work within a temperature range that goes from room temperature to 80°C; the tank features an automatic control system for convenient, safe, and reliable operation. Made entirely from stainless steel, it undergoes a meticulous internal and external mirror polish surface treatment. The agitating and holding tank, with its combination of precise temperature regulation and efficient mixing, is the best choice for different industrial applications where precise temperature control and effective mixing are crucial. -

Surface-cooling hot air cabinet

Our surface-cooling hot air cabinet is designed to improve the tablet coating process. It works by pulling air in with a fan. This air goes through several filters that clean it and take out moisture, making the air dry. Dry air is great for coating because it sticks better, improving the end result. After filtering, the air is heated, either with steam or electricity, and then sent into the drum. The cabinet also has a special part to keep it running smoothly without shaking. This cabinet is more than just a machine; it's a key part of doing a great job in tablet coating.

Jiangnan Enterprise is an experienced high efficiency tablet coating machine manufacturer and supplier in China. We provide various types of products such as high efficiency laboratory tablet coating machine, high efficiency poreless tablet coating machine, and high speed blister packaging machine.