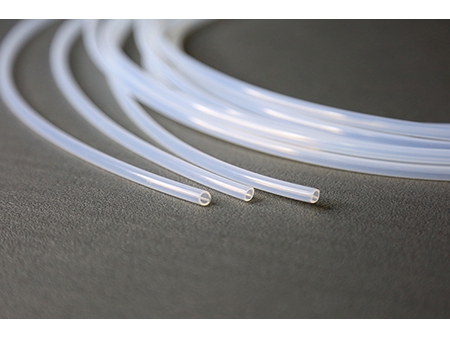

PTFE Heat Shrinkable Tubing

Request a Quote

CYG-PTFE

- Material: PTFE

- Shrink ratio: 2:1, 3:1

- Superior temperature resistance, corrosion resistance, oil resistance, and acid-alkali resistance

- Available in various shrink ratios

Applications

- Our PTFE heat shrink tubing is known for its superior high-temperature resistance, acid-alkali resistance, corrosion resistance, flame retardancy, and electronic insulation properties.

- It finds wide applications in electronic, mechanical, military, and aerospace industries, providing protection for electronic components against oil, corrosion, and insulation challenges.

Features

- Shrink ratio: 2:1, 3:1

- Superior temperature resistance, corrosion resistance, oil resistance, and acid-alkali resistance

- Available in various shrink ratios

- High flame retardancy

- Meets GJB 7275-2011 standards

| Properties | Test Method | Performance | |

| Operating temperature (℃) | - | --55~250 | |

| Water absorption (%) | 23℃/24h | ≤0.01 | |

| Longitudinal change (%) | - | -20~20 | |

| Tensile strength (MPa) | 50mm/min | ≥17.3 | |

| Ultimate elongation (%) | 50mm/min | ≥200 | |

| After aging 175℃/168h | Tensile strength (MPa) | 50mm/min | ≥17.3 |

| Ultimate elongation (%) | 50mm/min | ≥200 | |

| Dielectric strength (kV/mm) | - | ≥ 31.5 | |

| Insulation and voltage withstand | 2500V/60s | No breakdown | |

| Dielectric strength (kV/mm) | - | ≥ 31.5 | |

| Volume resistivity (Ω·CM) | - | ≥1.0×1018 | |

| Tensile strength (MPa) | 50mm/min | ≥17.3 | |

| Fluid resistance 23℃/24h | Ultimate elongation (%) | 50mm/min | ≥200 |

| Dielectric strength (kV/mm) | - | ≥ 31.5 | |

| Heat shock | 400℃/4h | No cracking | |

| Low temperature flexibility | -65℃/4h | No cracking | |

| Copper corrosion | 250℃/16h | No corrosion | |

| Flammability | - | Self-extinguishing within 15s | |

| Cold & heat shock test | -55℃, 200℃ | Tensile strength ≥17.3MPa; Ultimate elongation ≥200%; Dielectric strength ≥31.5kV/mm; | |

| Salt spray test | GJB 150.11 | Tensile strength ≥17.3MPa; Ultimate elongation ≥200%; Dielectric strength≥31.5kV/mm; | |

| Damp heat test | GJB 150.9 | Tensile strength ≥17.3MPa; Ultimate elongation ≥200%; Dielectric strength≥31.5kV/mm | |

| Fungal test | GJB 150.10 | Better than class 1 | |

Shrink Ratio: 2:1

| Size | As Supplied (mm) | After Recovery (mm) | |

| Minimum Inside Diameter | Maximum Inside Diameter | Wall Thickness | |

| Ø0.9 | 0.9 | 0.5 | 0.23±0.05 |

| Ø1.1 | 1.1 | 0.6 | 0.25±0.05 |

| Ø1.2 | 1.2 | 0.7 | 0.25±0.05 |

| Ø1.4 | 1.4 | 0.8 | 0.30±0.05 |

| Ø1.5 | 1.5 | 1.0 | 0.30±0.05 |

| Ø1.9 | 1.9 | 1.2 | 0.30±0.05 |

| Ø2.3 | 2.3 | 1.6 | 0.30±0.05 |

| Ø3.0 | 3.0 | 1.8 | 0.30±0.05 |

| Ø3.8 | 3.8 | 2.3 | 0.30±0.05 |

| Ø4.8 | 4.8 | 2.8 | 0.30±0.05 |

| Ø6.1 | 6.1 | 3.6 | 0.38±0.10 |

| Ø7.6 | 7.6 | 4.5 | 0.38±0.10 |

| Ø9.4 | 9.4 | 5.7 | 0.38±0.10 |

| Ø10.9 | 10.9 | 7.1 | 0.38±0.10 |

| Ø11.9 | 11.9 | 8.8 | 0.38±0.10 |

Shrink Ratio: 3:1

| Size | As Supplied (mm) | After Recovery (mm) | |

| Minimum Inside Diameter | Maximum Inside Diameter | Wall Thickness | |

| Ø2.0 | 2.0 | 0.6 | 0.23±0.05 |

| Ø3.2 | 3.2 | 1.0 | 0.25±0.05 |

| Ø6.4 | 6.4 | 1.6 | 0.30±0.05 |

| Ø9.5 | 9.5 | 2.4 | 0.30±0.05 |

| Ø12.7 | 12.7 | 3.7 | 0.38±0.10 |

| Ø19.1 | 19.1 | 5.7 | 0.38±0.10 |

| Ø25.4 | 25.4 | 7.1 | 0.38±0.10 |

| Ø31.8 | 31.8 | 8.8 | 0.38±0.10 |

| Ø38.1 | 38.1 | 10.2 | 0.38±0.10 |

| Ø50.8 | 50.8 | 13.2 | 0.51±0.13 |

Note: Custom sizes are available upon request.