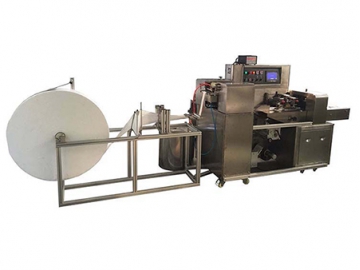

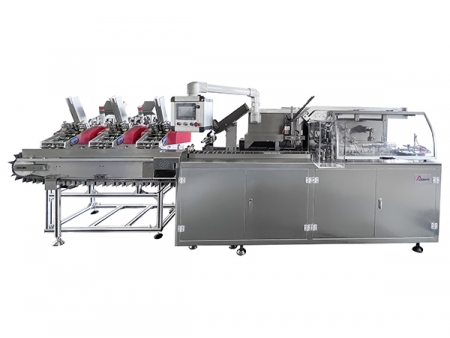

Fully Automatic Single Sachet Wet Wipes Machine

Request a Quote

DC-200 Wet Wipes Machine (1 pc/pack)

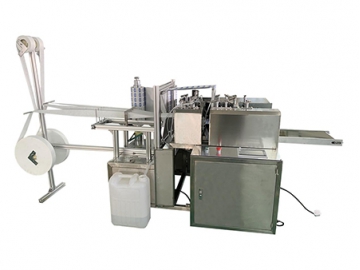

Wet wipes machine integrating folding, wetting, stacking, packaging and sealing

Key Parameters

Machine

- Production Speed 150-200 wipes per minute

- Fold Types Z-fold, W-fold

Product

- Open Wipe Length 160-260mm

- Open Wipe Width 150-250mm

- Folded Wipe Length 80-130mm

- Folded Wipe Width 40-85mm

This high-efficiency, fully automatic single-sachet wet wipe machine is designed to produce a wide variety of single-piece wet wipes, including wipes used in restaurant, disinfectant wipes, airline wipes, and feminine hygiene wipes.

With its user-friendly design, easy maintenance, and high-quality wet tissue production capabilities, this single-piece wet wipes machine is an ideal choice for entrepreneurs looking to enter the wet wipe industry. It significantly enhances production efficiency while catering to the diverse needs of customers.

Specifications

| Production speed | 150-200 wipes/min | Folded wipe width | 40-85mm |

| Quantity per pack | 1 wipe/pack | Fold type | Z-fold, W-fold |

| Wipe material | Spunlace fabric | Wrapping film | PE/PET, OPP/PE (aluminum metallized film) |

| Material weight | 40-80 g/m² | Package size | Length: 100-200mm Width: 50-90mm |

| Voltage | 380V 50HZ | Wetting system | Tank with agitator |

| Total power | 8.5kW | Liquid tank capacity | 400L |

| Parent roll width | 150-200mm | Machine dimensions (L×W×H) | 4940×1300×1690mm |

| Open wipe length | 160-260mm | Liquid tank size | 900×900×1900mm |

| Open wipe width | 150-250mm | Machine weight | 1500kg |

| Folded wipe length | 80-130mm | Production efficiency | >=85% |

Other Configurations

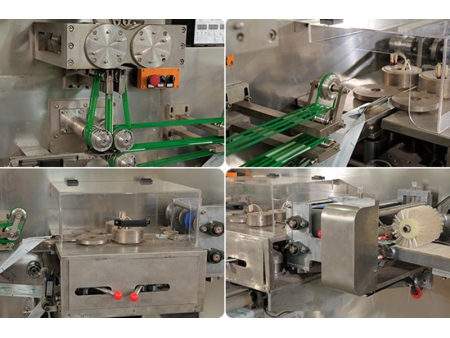

- Main electrical components: Mitsubishi (Japan)

- Pneumatic components: AirTAC (Taiwan)

- Key bearings: NTN/NSK (Japan)

- Transmission system: Enclosed gearbox timing belt universal coupling

- Motor control: Each motor can be independently started and stopped via the touch screen interface.

- Emergency stop features: Two emergency stop buttons and one pull-wire stop system; pressing any emergency stop halts the machine immediately.

- Operating interface: LCD touch display with real-time production parameter settings, daily production data recording and storage, MES data interface, and remote assistance and monitoring capabilities.

- Control modes: Offers both automatic and manual modes to suit production control needs.

- Fault alerts: Automatic shutdown or alarm notifications in case of equipment malfunction.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos