Air brake fittings

The push-in hose barb fittings are primarily used to connect components within the compressed air systems of commercial vehicles. These fittings allow for the quick assembly of nylon tubes to the corresponding pneumatic devices and brake or air suspension systems. Designed to withstand temperatures ranging from -45°C to 104°C, they can handle a maximum working pressure of 15 bar. These fittings are compatible with nylon tubes made from PA11 and PA12 and meet the QC/T80 and DIN74324 standards.

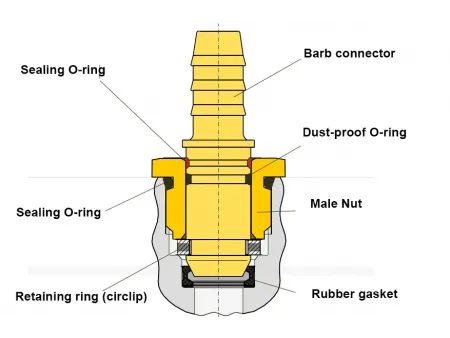

The push-in fittings consist of two main parts:

- Connector body: Composed of a nut seat, snap ring, elastic washer, O-ring, and transition connector body

- Plug body: Includes the plug body itself and an O-ring for sealing

The nut seat or transition connector body connects to ports that meet the JED-388 standard via threading, while the plug body is secured to the inner bore of the nylon tube through a barb connection. This ensures a quick and secure connection when the plug body is inserted into the corresponding nut seat. The main materials used for the connector body are brass, while the plug body can be made of brass or nylon. This connection method is both safe and reliable, and is widely used in major commercial vehicle models across domestic and European markets.

Key Parameters

- Main materials include brass, plastic, and rubber

- Connects to ports that meet JED-388 standards

- Suitable for compressed air applications

- Operating temperature: -45°C to 104°C

- Maximum working pressure: 15 bar

Advantages

These fittings are used with automotive nylon tubes in the compressed air systems of commercial vehicles, replacing traditional metal tubes. Nylon tubes offer resistance to vibrations and frame deformation, making them easier to handle and install in any part of the vehicle compared to metal alternatives.

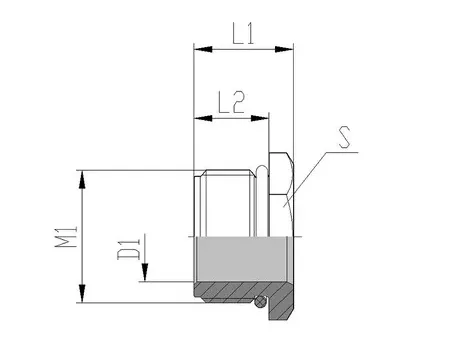

Male Nut (Air Brake Nut)

| Model | M1 | S | L1 | L2 | D1 | Connection Size |

| B2300M10G06 | M10×1 | 12 | 10.2 | 6 | 6.3 | NG06 |

| B2300M16G08 | M16×1.5 | 19 | 16.5 | 12.5 | 9.5 | NG08 |

| B2300M22G12 | M22×1.5 | 24 | 16.5 | 12.5 | 15 | NG12 |

Retaining Ring (Circlip)

| Model | L1 | L2 | T1 | T2 | Connection Size |

| B2300001G06 | 7.3 | 8.1 | 2.5 | 1.1 | NG06 |

| B2300001G08 | 11.6 | 14.3 | 3 | 2.3 | NG08 |

| B2300001G12 | 20.1 | 24 | 3 | 2.6 | NG12 |

Gasket

| Model | D1 | D2 | T | Connection Size |

| B2300002G06 | 6.4 | 3.4 | 3.3 | NG06 |

| B2300002G08 | 9.7 | 5.4 | 4 | NG08 |

| B2300002G12 | 15.2 | 10.9 | 4 | NG12 |

Blanking Plug

| Model | M1 | L1 | L2 | S | Connection Size |

| B2300M10T00 | M10×1 | 6 | 10 | 12 | NG06 |

| B2300M16T00 | M16×1.5 | 10 | 14 | 19 | NG08 |

| B2300M22T00 | M22×1.5 | 10 | 14 | 24 | NG12 |

Hose Barb Swivel

| Model | M1 | S | L1 | L2 | Tube Size |

| B2301Q12W04 | M12×1.25 | 14 | 35 | 16 | 6×1 |

| B2301Q14W06 | M14×1.5 | 17 | 38 | 16 | 8×1 |

| B2301Q16W07 | M16×1.5 | 19 | 41 | 22 | 10×1.25 |

| B2301Q18W09 | M18×1.5 | 21 | 41 | 22 | 12×1.5 |

Hose Barb Joiner

| Model | D1 | L1 | L2 | L3 | Tube Size |

| B2301W04W04 | 12 | 41 | 16 | 16 | 6×1 |

| B2301W06W06 | 15 | 41 | 16 | 16 | 8×1 |

| B2301W07W07 | 15 | 53 | 22 | 22 | 10×1.25 |

| B2301W09W09 | 16 | 53 | 22 | 22 | 12×1.5 |

| B2301W10W10 | 16 | 53 | 22 | 22 | 14×2 |

| B2301W11W11 | 16 | 59 | 25 | 25 | 14×1.5 |

| B2301W12W12 | 16 | 59 | 25 | 25 | 16×2 |

Hose Barb Straight Adaptor

| Model | D1 | L1 | L2 | Tube Size | Connection Size |

| B2301N06W04 | 6.3 | 33.5 | 16 | 6×1 | NG06 |

| B2301N08W04 | 9.4 | 43.5 | 16 | 6×1 | NG08 |

| B2301N08W06 | 9.4 | 43.5 | 16 | 8×1 | NG08 |

| B2301N08W07 | 9.4 | 49.5 | 22 | 10×1.25 | NG08 |

| B2301N08W09 | 9.4 | 49.5 | 22 | 12×1.5 | NG08 |

| B2301N12W04 | 14.9 | 43.5 | 16 | 6×1 | NG12 |

| B2301N12W06 | 14.9 | 43.5 | 16 | 8×1 | NG12 |

| B2301N12W07 | 14.9 | 49.5 | 22 | 10×1.25 | NG12 |

| B2301N12W09 | 14.9 | 49.5 | 22 | 12×1.5 | NG12 |

| B2301N12W10 | 14.9 | 49.5 | 22 | 14×2.0 | NG12 |

| B2301N12W11 | 14.9 | 52.5 | 25 | 14×1.5 | NG12 |

| B2301N12W12 | 14.9 | 52.5 | 25 | 16×2.0 | NG12 |

Hose Barb Elbow

| Model | D1 | L1 | L2 | L3 | Tube Size |

| B2302N06W04 | 7.3 (6.3) | 22 | 24 | 16 | 6×1 |

| B2302N08W04 | 9.4 | 33 | 24 | 16 | 6×1 |

| B2302N08W06 | 9.4 | 33 | 24 | 16 | 8×1 |

| B2302N08W07 | 9.4 | 34 | 33 | 22 | 10×1.25 |

| B2302N08W09 | 9.4 | 35 | 33 | 22 | 12×1.5 |

| B2302N12W04 | 14.9 | 35 | 26.5 | 16 | 6×1 |

| B2302N12W06 | 14.9 | 35 | 26.5 | 16 | 8×1 |

| B2302N12W06 L | 14.9 | 50 | 26.5 | 16 | 8×1 |

| B2302N12W07 | 14.9 | 35 | 32.5 | 22 | 10×1.25 |

| B2302N12W09 | 14.9 | 35 | 32.5 | 22 | 12×1.5 |

| B2302N12W09 P | 14.9 | 36.5 | 39 | 29.5 | 12×1.5 |

| B2302N12W09 L | 14.9 | 46 | 32.5 | 22 | 12×1.5 |

| B2302N12W10 | 14.9 | 35 | 32.5 | 22 | 14×2 |

| B2302N12W11 | 14.9 | 37 | 35.5 | 25 | 14×1.5 |

| B2302N12W12 | 14.9 | 37 | 35.5 | 25 | 16×2 |

Hose Barb Tee

| Model | L1 | L2 | L3 | L4 | L5 | L6 |

| B2304W04W04W04 | 22 | 16 | 22 | 16 | 22 | 16 |

| B2304W06W06W06 | 22 | 16 | 22 | 16 | 22 | 16 |

| B2304W07W07W07 | 29 | 22 | 29 | 22 | 29 | 22 |

| B2304W09W09W09 | 29 | 22 | 29 | 22 | 29 | 22 |

| B2304W10W10W10 | 29 | 22 | 29 | 22 | 29 | 22 |

| B2304W11W11W11 | 34.5 | 25 | 34.5 | 25 | 34.5 | 25 |

| B2304W12W12W12 | 34.5 | 25 | 34.5 | 25 | 34.5 | 25 |

| B2304W06W04W06 | 22 | 16 | 22 | 16 | 22 | 16 |

| B2304W06W09W09 | 23 | 16 | 29 | 22 | 29 | 22 |

| B2304W09W06W09 | 29 | 22 | 23 | 16 | 29 | 22 |

| B2304W12W09W12 | 33 | 25 | 30 | 22 | 33 | 25 |

| Model | D1 | L1 | L2 | L3 | L4 | L5 | L6 |

| B2304W06N08W06 | 9.4 | 35 | 26 | 24 | 16 | 24 | 16 |

| B2304W06N08W09 | 9.4 | 35 | 26 | 24 | 16 | 30 | 22 |

| B2304W06N12W06 | 15 | 35 | 26 | 26.5 | 16 | 26.5 | 16 |

| B2304W06N12W09 | 15 | 35 | 26 | 26.5 | 16 | 32.5 | 22 |

| B2304W07N12W07 | 15 | 35 | 26 | 32.5 | 22 | 32.5 | 22 |

| B2304W09N12W09 | 15 | 35 | 26 | 32.5 | 22 | 32.5 | 22 |

| B2304W10N12W10 | 15 | 35 | 26 | 32.5 | 22 | 32.5 | 22 |

| B2304W11N12W11 | 15 | 35 | 26 | 35.5 | 25 | 35.5 | 25 |

| B2304W12N12W12 | 15 | 35 | 26 | 35.5 | 25 | 35.5 | 25 |

| Model | D1 | L1 | L2 | L3 | L4 | L5 | L6 |

| B2305N06W04W04 | 6.3 | 21 | 16 | 22 | 16 | 22 | 16 |

| B2305N08W06W06 | 9.4 | 33 | 26 | 22.5 | 16 | 24 | 16 |

| B2305N12W06W06 | 15 | 35 | 26 | 26.5 | 16 | 26.5 | 16 |

| B2305N12W06W09 | 15 | 35 | 26 | 30.5 | 22 | 26.5 | 16 |

| B2305N12W07W07 | 15 | 35 | 26 | 30.5 | 22 | 32.5 | 22 |

| B2305N12W09W09 | 15 | 35 | 26 | 30.5 | 22 | 32.5 | 22 |

| B2305N12W09W12 | 15 | 35 | 26 | 33.5 | 25 | 32.5 | 22 |

| B2305N12W10W10 | 15 | 35 | 26 | 30.5 | 22 | 32.5 | 22 |

| B2305N11W11W11 | 15 | 35 | 26 | 33.5 | 25 | 35.5 | 25 |

| B2305N11W12W12 | 15 | 35 | 26 | 33.5 | 25 | 35.5 | 25 |