Quarry Wire Saw Machine

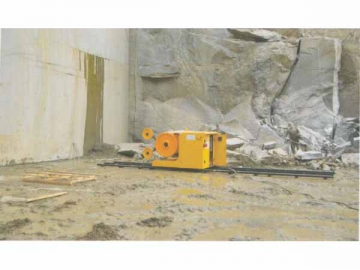

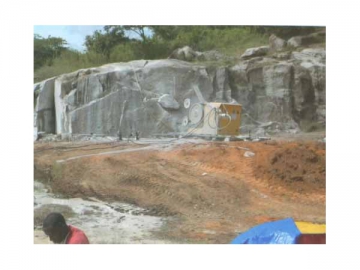

Even the toughest of quarrying environments is no match for Huada wire saw machine. For any size of quarry, we can put together an end-to-end quarrying solution, from laying tracks (on which the wire saw runs), through on-site installation and commissioning, to servicing and repair.

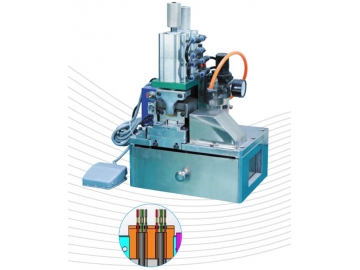

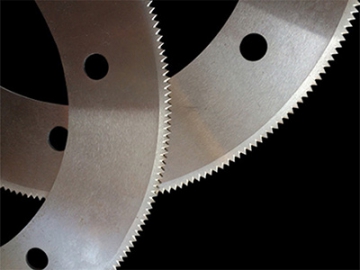

Featuring time-tested, field-proven technology, Huada’s robust and hardworking range of diamond wire saw machines delivers unrivalled durability and reliability. Unique electric feed control allows operators to feed the diamond wire slowly into the mass of rocks to be cut.

The addition of a middle rail to the track reduces the risk of the wire saw sliding off the rail while preventing the track from catching any mud on the quarry site. Gear-driven feed system enables accurate positioning of the wire saw even on the steepest slopes.

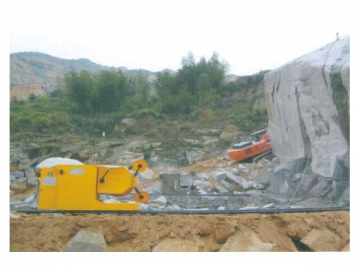

Fast-spinning aluminum flywheel directly connects the motor crankshaft to minimize power loss. The machine can rotate 360°to make virtually any angled cuts. The wire saw can move 30 cm in the cross-machine direction, and make two vertical cuts 160cm apart in the machine direction without the need to move the machine. Horizontal cuts can also be made.

As reserves are running short on quarry sites across the country, making the most use of quarry resources becomes imperative. Huada diamond wire saw machine provides a cost effective way of quarrying as more and more quarry workers are using wire sawing technology for demolition of mass stones.

Features of Huada Wire Saw Machine

1. Offers automatic control of wire tension and machine’s moving speed.

2. Allows free switch from manual mode to automatic mode, and vice versa.

3. Delivers consistently high efficiency by varying sawing speeds according to the varied loads on the track.

Note: The reinforced wire saw machine comes with Schneider system control. All VFDs and other electric elements are from Schneider and designed specifically for use in extremely tough quarrying environments.

Reinforced Wire Saw for Granite| Model | Main motor power | Length of wire (m) | Line speed(m/s) | Remark |

| DWS-37AX-8PG | 37KW | 20-80 | 0-30 | |

| DWS-55AX-8PG | 55KW | 20-120 | 0-30 | |

| DWS-75AX-8PG | 75KW | 20-150 | 0-50 | |

| DWS-90AX-8PG | 90KW | 30-160 | 0-50 | |

| DWS-110AX-8PG | 110KW | 40-180 | 0-50 |

| Model | Main motor power | Length of wire(m) | Line speed (m/s) | Remark |

| DWS-37AX-6PG | 37KW | 20-80 | 0-40 | |

| DWS-45AX-6PG | 45KW | 20-100 | 0-40 | |

| DWS-55AX-6PG | 55KW | 20-120 | 0-40 | |

| DWS-75AX-8PG | 75KW | 20-150 | 0-50 | |

| DWS-90AX-8PG | 90KW | 30-160 | 0-50 | |

| DWS-110AX-8PG | 110KW | 40-180 | 0-50 |

As well as providing all the features seen in a standard wire saw machine, the reinforced unit delivers other functions.

1. Adapts to virtually any quarrying environments. The variable frequency drive controls the machine moving speed, wire feed rate, and movement in the cross-machine direction.

2. More stable performance due to system modification.

3. The limit switch is a great addition to the motor, allowing it to turn in ±180° range.

4. Adding the fault warning feature to the control panel makes it easier for users to analyze machine fault and reduce unscheduled downtime.

5. Available with two speeds, the running gear enables a maximum machine moving speed up to 3m/min.

| Model | Main motor power | Length of wire(m) | Line speed (m/s) | Remark |

| DWS-37AX-6PG | 37KW | 20-80 | 0-40 | |

| DWS-45AX-6PG | 45KW | 20-100 | 0-40 | |

| DWS-55AX-6PG | 55KW | 20-120 | 0-40 | |

| DWS-75AX-8PG | 75KW | 20-150 | 0-50 | |

| DWS-90AX-8PG | 90KW | 30-160 | 0-50 | |

| DWS-110AX-8PG | 110KW | 40-180 | 0-50 |

| Model | Main motor power | Length of wire(m) | Line speed (m/s) | Remark |

| DWS-37AX-8P | 37KW | 20-80 | 0-30 | |

| DWS-55AX-8P | 55KW | 20-120 | 0-30 | |

| DWS-75AX-8P | 75KW | 20-150 | 0-50 | |

| DWS-90AX-8P | 90KW | 30-160 | 0-50 | |

| DWS-110AX-8P | 110KW | 40-180 | 0-50 |

Features

1. Available with two variable frequency drives, for adjustment of wire feed rate and machine moving speed respectively. Paired with PLC system for automatic control of wire tension and wire sawing process.

2. In automatic mode, the wire saw machine constantly adjusts its speed to match the changing loads on the quarry site. A consistently high working efficiency can be achieved.

3. Safety features provide maximum protection in the event of wire break, overload, phase loss, and overrunning.

4. Turning, traverse movement, and rapid running functionality.

5. The running gear operates in two speeds, delivering a maximum speed of 3m/min.

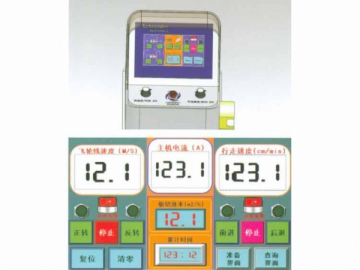

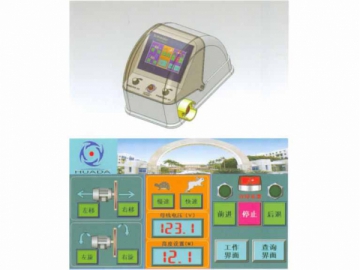

Schneider TouchScreen

1. A transparent protective cover keeps out dust and moisture while allowing users to view the inside screen without needing to lift up the cover. The cover is made of engineering plastic.

2. Schneider touchscreen allows easy access, displaying working status in real time.

3. Via operating the touchscreen, operators can gain a basic knowledge of the wire saw machine. The added search window provides a list of common machine faults and troubleshooting methods, assisting operators in fault analysis.

4. Power cables are 12-core cables as compared to 44-core ones previously encountered. They are easy to carry, plug in and out.

5. The running gear offers 2 speeds, allowing the wire saw to work on a large rock surface as well as for shaping raw blocks.

6. Guide rails on both sides of the machine are lighter than traditional rails, easy to carry and enable horizontal cuts on rocks closer to the ground.