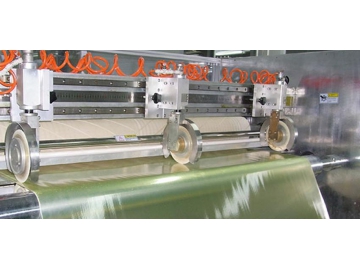

PP / Copper Foil Slitting Machine

With the introduction of PCB and CCl, the slitting machine can cut both prepreg and copper foil into correct sizes, and pairs well with the automatic stacking equipment.

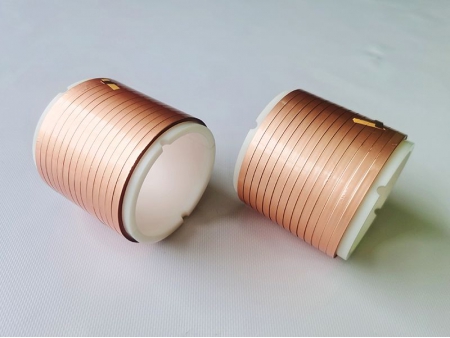

Cut materialsPP (Prepreg), PVC (polyvinyl chloride), copper foil, aluminum foil, tinfoil, paper, sticker and so on.

ParametersSlitting width: 10~1350mm;

Slitting thickness: 0.02mm~0.25mm;

Slitting speed: 0~60m/min, adjustable;

Cutter movement: 0~18times/min, adjustable and custom designing;

Slitting length: 0.1m~9999m, custom designing (length of collecting table: 1100mm);

Slitting accuracy: length error ±0.5mm/m;

Accuracy of diagonal error: ±1mm/m;

Blade quality: sliding constantly more than 10000 times;

Power: 1.5KW (2HP) AC380V;

Choose to buy: cutter with high hardness, efficient dust collection system;

- The Mitsubishi servo-control system can save materials through an accurate slitting process.

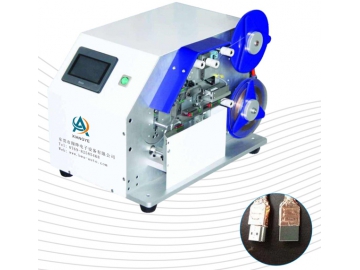

- The operation panel with a touch screen is convenient to set and maintain the cutting parameters.

- Three groups of aluminum alloy blades with a matching dovetail mount facilitate a fast location and cutting of plates.

- Cutting and slitting at the same time can reduce manual operation and delivery times, thus effectively improving both capacity and speed,

- The scissor cutting system can adjust the gap between the cutters to suit different material types and thicknesses, thus prolonging the cutter service life.

- The expanding air shaft is made of aluminum alloy material that is both lightweight and durable.

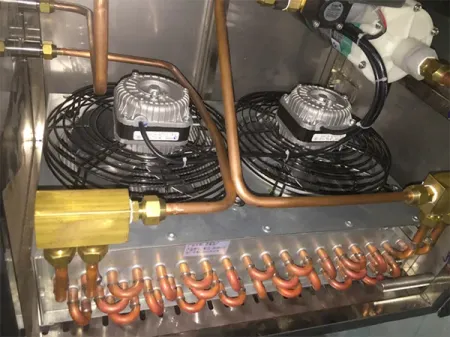

- Tension control is found in the unwinding process, with a fast response speed, no noise, and energy saving performance.

- A rubber roller is used for material conveying, and the concentricity between each tire is less than 0.02 mm, thus achieving a smooth conveyance process.

- An auto-lifting feeder can be added according to customer requirements.