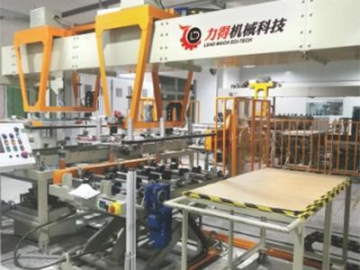

PCB Board Layer Stacking Machine

LEAD optimize the stacking process of copper foil and inner layer (prepreg and inner circuit board) to achieve whole-automatic operation of multiple PCB layers, including cutting of copper foil, stack-up of multiple layers, as well as stripping, cutting and packaging of steel plate.

Manufacturing processThe PCB layer stacking machine stacks multiple layers of steel plates, copper foils, inner layer and copper foils using press loading equipment. The resulting semi-finished PCB is stripped from the steel plate by the manipulator, then transferred to the next unit for further processing. The steel plate is then conveyed back to the steel plate cleanser for recycling after cleaning. by press loading equipment. The resulting semi-finished PCB is stripped from steel plate by manipulator, and then transferred to next unit for further processing. The steel plate is conveyed back to steel plate cleanser, which can be recycled after cleaning.

- Automatic stack-up

- Automatic breakdown

- Automatic returning of steel plate

Automation

The multiple PCB layers can achieve on-line automatic cutting and stack-up without the need for manual operation.

Low energy consumption

In order to decrease energy consumption and optimize the control system, the capacity of every unit is calculated, with custom design an essential process.

Uses

Automatic arranging of plates

- Stacking mode: automatic stack up layers of copper foil, steel plate, copper foil;

- Stacking accuracy: ±1.5mm;

- Stacking speed: 12 seconds/layer

Uses

The Suction hoist can separate steel plates and semi-finished PCB

- Breakdown mode: separated by manipulator

- Separating speed: 12 seconds/layer

- Intelligent control: achieve remote monitoring, reserve PLC interface and ERP interface

Uses

The Suction hoist can stack the steel plate and multiple layers.

- Breakdown mode: separated by manipulator

- Separating speed: 12 seconds/layer