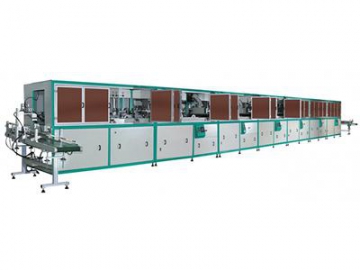

Rotary Table Bottle Packaging Printing Machine

Application

The rotary table bottle packaging printing machine was developed by Timey to apply labels to hosepipe, plastic bottles, acrylic bottles, and other round products.

| Max printing area | 250x150mm |

| Min bottle dia. | Φ20mm |

| Max bottle dia. | Φ80mm |

| Min bottle height | 20mm |

| Max bottle height | 200mm |

| Max screen frame size | 400x300mm |

| Max printing speed | 4800pcs/hr |

Features

1. The automatic rotary table bottle packaging printing machine features a rotary design with a mechanical transmission and combined PLC system. The entire machine is easy to operate and provides high quality printing with outstanding accuracy.

2. The machine meets the various needs of customers for their dynamic printing processes. It can minimize the consumption of resources and improve overall production efficiency.

3. Depending on the requirements necessary for the customer, we have the ability to set up an automatic placement and sorting system for raw materials used in the printing process. This saves manpower, resources, and improves overall efficiency.

4. After inspecting the process requirements of specialized products, the operator can select an automatic positioning device, coating oil device, and QR code application device.

Our rotary table bottle packaging printing machine is suitable for printing on water bottles, medical containers, cosmetic bottles, etc. We have all the production resources to make screen printing machines with custom service.