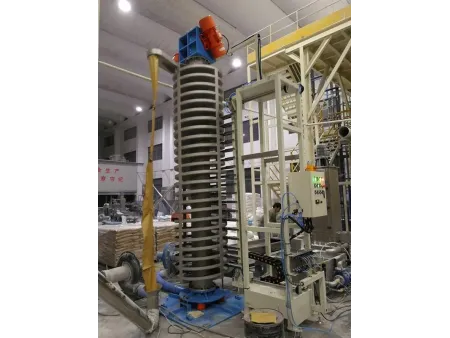

Continuous Vibrating Elevator and Dryer

Request a Quote

Applications

The continuous vibration dryer is suitable for heating and drying of materials in a continuous drying operation.

Operational Principle

This vibration spiral elevator is designed with heating function. The material is heated using the jacketed vibratory plate during the long-distance vibration transmission, thus ensuring the water vapor dries faster with a better drying effect.

Parameter

| | | | | |

| 500-600 | 800-1000 | 1000-2000 | 3000-4000 | 3000-5000 |

| Ø600 | Ø800 | Ø1000 | Ø1300 | Ø1600 |

| 600 | 640 | 700 | 700 | 700 |

| 3000 | 3000 | 3000 | 3000 | 7000 |

| 0.55*2 | 1.1*2 | 1.7*2 | 2.3*2 | 6.2*2 |

| Hot water, steam, heating plate, thermal oil | ||||

| 3-4 | 3-4 | 3-4 | 3-4 | 7-8 |

Features

- The continuous vibrating elevator and dryer achieves drying, lifting and conveying.

- There is no extrusion of the mechanical force during the conveying process, thus ensuring it meets requirements for non-destructive transport occasions.

- Small footprint

- The heat conduction medium heats the materials using the jacket and solves issues caused by a low energy efficiency of the hot air in the drying of a traditional boiling bed. This leads to a higher, better effect than hot air drying.

- There has no accumulation of material, and it will dry evenly due to material movement during continuous rolling vibration.

- Heating mediums include infrared, hot water, steam and heat transfer oil, and the heating temperature can be controlled.

- The feeding section is cooled using a jacket to avoid damping.

- Because there is no external forced hot air entry, impurities that can contaminate materials in the hot wind are avoided.

- The materials can be made for top infeed and bottom outfeed or bottom infeed and top outfeed both of which utilize a customized height, according to customer needs.

- A removable thermal insulation jacket structure can be designed in order to improve the thermal efficiency.

- The continuous vibration dryer can be equipped with closed intake and exhaust structure to avoid environmental pollution of powdery materials.

- It can add nitrogen gas protection to prevent materials from oxidizing and deteriorating during high temperature work.

- It can add a wear-resistant ceramic veneer layer to adapt to the long-term transportation of high hardness products.

- Dry and lifting of different material types can be continued after a quick cleaning due to the easy cleaning of the machine.

- It adjusts the conveying speed and output of materials to meet the drying time requirements for different materials by adjusting the vibration frequency and the excitation force.

Benefits

- The energy consumption is significantly reduced and the comprehensive benefits are significantly improved.

- The drying process conditions are flexible and can be automatically controlled.

- The material quality is improved and stable after drying.

- Continuous operation makes the operation simple and efficient.

- Improve the working environment of workers.

Tags

drying equipment, dryer, vertical conveying