Stainless Steel Water Storage Tank Seam Welding Spot Welding Machine Line

The stainless steel water storage tank seam welding spot welding machine line is used in the production of 500 to 2000L stainless steel water tanks with a thickness of 0.3 to 1.3mm and a diameter of 700 to 3200mm.

Configuration

FZ-100 water tank seam welding machine, 1050 spot welding machine, 3200 double electric rolling machine, 1300 rolling machine, triangle iron bending machine

Description

The FZ-100 water tank seam welding machine uses DC electric welding, which saves up to 30% more power when compared to a traditional AC water tank seam welding machine. This tank welding equipment features a high welding strength, excellent tightness, and will not leak. Both circumferential seam welding and straight seam welding are available, reducing overall costs. Not only that, but the machine has been designed based on the production requirements of large water tanks, and can thus meet production requirements, and various specifications of different tank types.

| Model | FZ-100 |

| Rated capacity | 100KVA |

| Rated voltage input | 380V/50hz |

| Welding thickness | 0.3~1.5mm |

| Welding speed | 0.3~1.5m/min adjustable |

| Arm dimension | 1600mm |

| Weight | 800kg |

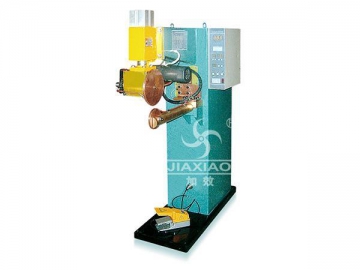

The 1050 spot welding machine is mainly used for the spot welding fastening of the plate, cover, and body of the stainless steel water tank. With an adjustable machine head, welding is easy and convenient.

Model: 1050

Power: 35KVA

Welding thickness: 0.3-0.6mm

Arm length: 1.25m

Control box: JX-01 microcomputer controller

Weight: 240kg

The 3200 double electric rolling machine features electric lifting and rolling functions, and is a new, high quality piece of equipment for water tank steel rolling. It is more convenient and efficient than pneumatic and manual rolling.

Parameters| Model | 3200 |

| Power | 1.5KW |

| Power supply | 380V/50hz |

| Roller thickness | 0.3~1.5mm |

| Roller diameter | 600-3200mm |

| Arm length | 1300 mm |

| Roller speed | 3 bars 3 group |

The 1300 single rolling machine is designed based on the production requirements of large water tanks, and can be made in accordance with different specifications and types of water tanks. This equipment is primarily used in the production of single reinforcement stainless steel water tanks, making it an ideal choice for residential and industrial water tanks alike.

Parameters| Model | 1300 |

| Power | 0.75KW |

| Power supply | 380V/50hz |

| Roller thickness | 0.3~1.5mm |

| Roller diameter | 600-3200mm |

| Arm length | 1300 mm |

| Model | Triangle |

| Power | 1.1 Kw |

| Reduction ratio | 1:43 |

| Voltage | 380 V/50 HZ |

| Phase number | Three-phase |

| Angle iron size | 30×3 mm |

| Pressurization method | Manual pressurization |

| Minimum diameter | 50 cm |

| Weight | 130 Kg |

| Outline size | 560×400×1100 mm |

Jiaxiao is a leading electric resistance welding equipment manufacturer since 1992, besides this stainless steel water storage tank welding line, we offer a wide range of resistance spot welder, projection welder, seam welding machine with custom solutions. Equipped with advanced machining and assembly machines, our company provides quality stainless steel seam welding and spot welding system to the global clients.