SGS1525/2040T-3S 3-axis Gantry CNC Machine

Request a Quote

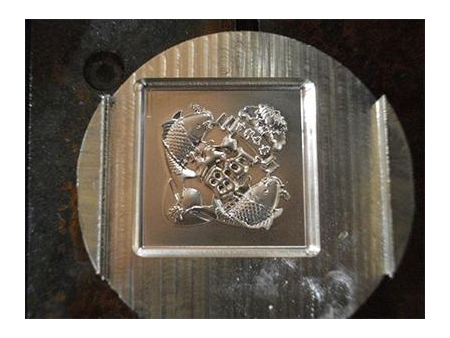

This 3-axis gantry CNC machine is heavy-duty processing equipment that is suitable for the production of aluminum molds as well as wood molds and foam models. The maximum workpiece dimensions the machine can process is 2500 x 1500 x 400mm (length x width x thickness).

Materials Cut

It can process wood workpieces with nails, fiber reinforced plastic, foam, plastic, and soft metal such as aluminum.

Applications

The CNC machine is widely applied in the mold industry for the manufacturing of large aluminum molds as well as non-metal molds.

Features

- The cast iron table can conveniently and firmly fix workpieces of various sizes to ensure optimal stability during processing.

- The machine body is seamlessly welded using thick wall square steel. The equipment will not deform even after many years of heavy use.

- The Z axis is equipped with a cast iron rolling board. The HIWIN guide rail ensures stable processing and precise machining.

- The X and Y axes use a screw drive to enhance accuracy.

- Using a professional screw drill machine, the screw of this CNC machine is installed vertically and firmly.

- The nitrogen gas balancing cylinder provides an upwards pushing force to reduce the load on the Z axis, protecting sensitive components.

- The BT40 spindle is made in Taiwan. The spindle power is 7.5kW and its speed is 0-18000r/min.

Parameters

| Model | F2-SGS1525T | F2-SGS2040T | F2-SGS2540T | F2-SGS3040T | F2-SGS3050T |

| X-axis stroke | 1500mm | 2000mm | 2500mm | 3000mm | 3000mm |

| Y-axis stroke | 2500mm | 4000mm | 4000mm | 4000mm | 5000mm |

| Z-axis stroke | 600mm | 1000mm | 1000mm | 1000mm | 1000mm |

| Max. shank diameter | Ф32mm | ||||

| Max. feed rate | X-axis:30000mm/min, Y-axis: 30000mm/min, Z-axis: 8000mm/min | ||||

| Accuracy | ±0.1mm | ||||

| Repeatability | X-axis:0.03mm, Y-axis:0.03mm, Z-axis:0.02mm | ||||

| Processing speed | 0-15000mm/min | ||||

| Power | 20KW | ||||

| Working voltage | AC 380V/50HZ (Adjustable) | ||||

| Pressure | 6.5Kgf/² | ||||

Optional Device

- An additional rotary axis can be added with a length of 2000mm and diameter of 300mm.

- Software such as UG, Mastercam, and Powermill are optional.

Gallery