Falling Film Evaporator

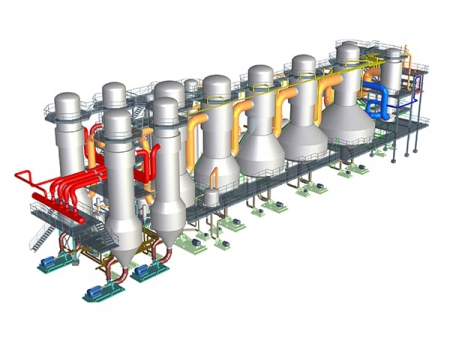

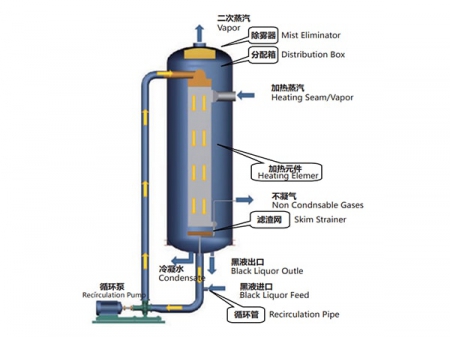

The multiple effect evaporator employs falling film evaporation principle to boil the dilute solution. In this process, part of the water will vaporize thus the solution is concentrated. This evaporator set adopts continuous production style. With large concentration ratio (1/5-1/10), wide viscosity range (<400CP), good heat transfer effect, and large production capacity, falling film evaporator is suitable for processing heat sensitive or corrosive materials with high concentration and large viscosity. It has been widely applied in the concentration of corn steep liquor, maltose solution, juice, monosodium glutamate solution, milk, syrup and distiller's grain slurries in starch, dairy, sugar, and alcohol industries, etc.

This evaporator equipment is designed with large heat transfer coefficient and requires little difference in thermal transferring. According to the properties of materials and purpose of evaporating, it can be combined into 2-stage, 3-stage, 4-stage, and 5-stage evaporation system. Besides, it is able to utilize the heat of the waste gas exhausted by the bundle dryer/disc dryer or other heat source with low calorific value (like condensation of water vapor). In this way, the evaporator contributes a lot to save and utilize energy. When the waste steam supplied adequately, it is even unnecessary to power it additionally.

Technical Parameters| Model | |||||||||

| Evaporated volume (kg/hr) | 3000 | 6000 | 9000 | 15000 | 20000 | 30000 | 50000 | 100000 | |

| Steam consumption | 900 | 1800 | 2700 | 4500 | 4500 | 9000 | 15000 | 30000 | |

| Vacuum degree | 1st stage | 0 | |||||||

| 2ndstage | |||||||||

| (mmHg) | 3rdstage | ||||||||

| Temperature for evaporation | 1st stage | 99 | |||||||

| 2ndstage | |||||||||

| 3rdstage | |||||||||

| Steam pressure (Mpa) | 0.6-1.0 (absolute pressure) | ||||||||

| Solid content (before) (%) | 6-7 (corn steep liquor) | ||||||||

| Solid content (after) (%) | 42-48 (corn steep liquor) | ||||||||