Flush Self-Pierce Riveting System

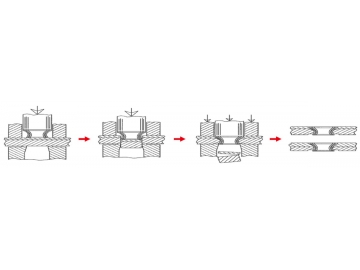

During the flush self-pierce riveting (FSPR) process, the riveting machine automatically feeds rivets into riveting head. By pressing, material got sheared and sent-out by rivet, which is then pressed and formed by tooling underneath to join two parts together.

Flush Self-Pierce Riveting ProcessZM6 servo flush self-pierce riveting (FSPR) gun features an integrated internal strain-gauge force sensor (80 kN), making it ideal for high-precision riveting based on force- and displacement-controlled monitoring. This FSPR riveting gun optimized the machine's overall weight and minimized installation space. At the same time, the balanced center-of-gravity design ensures excellent performance when integrated with robot arms.

| Model # | ZM6-080-C22001 | |

| Power Supply | V/⌀/Hz | 220/1/50 |

| Max Air Pressure | MPa | 0.5 |

| Press Force | kN | 80 |

| Total Stroke | mm | 100 |

| Power Stroke | mm | 10 |

| Dimensions (LxWxH) | mm | 827x213x1526 |

- Offers up to 40% reduction in rivet edge distance compared with traditional self-pierce riveting (SPR) systems.

- Supports multi-layer stacks up to 9.1 mm thick.

- Joint strength up to 1,800 MPa.

- Produces flush and reliable joints formation without affecting the downstream body design.

- Minimal workpiece deformation enables stable joining of mixed materials, such as carbon fiber aluminum and high-strength steel die-cast aluminum.

- Features a modular design that allows fast die changes and quick adjustments.

- Significantly reduced tool-change frequency compared with conventional SPR.

- Integrated online quality monitoring and closed-loop control ensure real-time assessment and consistent process stability.

The stationary self-piercing riveting machine applies floor-standing structure with good body rigidity; pressing process is performed by pneumatic-hydraulic power cylinder.

Specifications| Model | ZMY-008-001-18002 | |

| Power supply | V/Φ/Hz | 220/1/50 |

| Max. air pressure | Mpa | 0.6 |

| Press force | kN | 74 |

| Total stroke | mm | 100 |

| Power stroke | mm | 12 |

| Dimensions (LxWxH) | mm | 800x960x2400 |

- High operation speed & press force output

Compressed air is applied to power the pressing process. With an air/oil pressure conversion mechanism, high operation speed and high press force output can be achieved; press force output can be adjusted conveniently as well; a better performance is thus granted compared with traditional hydraulic pressing devices. - Convenient adjustment and maintenance

The pressing force output is adjustable in both normal-pressure process and pressure-boosted process, which can be achieved by simply adjusting input air pressure; the device is thus more convenient for maintenance, and lower cost is therefore granted. - Automatic and safe

The stationary self-piercing riveting machine equips full-auto control system, in which manual mode is also offered with emergency stop and up/down inching switch functions; real-time running status can be acquired conveniently, which grants better efficient and safety; time consumption of shutdown maintenance is therefore reduced, thus granting lower labor cost and better safety.

The attachable flush self-pierce riveting machine is highly integrated, equipped with test and control functions. Automatic control is achieved by a simple connection between the riveting machine and robot or workstation.

Communication protocols between riveting plier and PLC or robot is customizable, options include profinet, cc-link, etc.

Specifications| Model | F04-000734 | |

| Power supply | V/Φ/Hz | 220/1/50 |

| Max. air pressure | Mpa | 0.5 |

| Press force | kN | 80 |

| Total stroke | mm | 100 |

| Power stroke | mm | 10 |

| Dimensions (LxWxH) | mm | 1000x1000x2400 |