Plastic Molding Solution for Home Appliance

Request a Quote

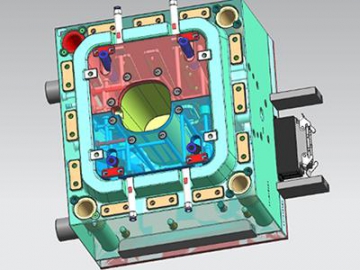

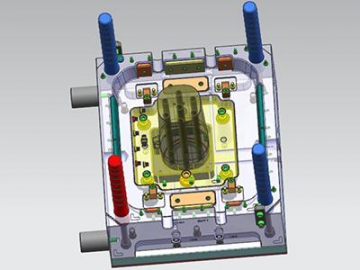

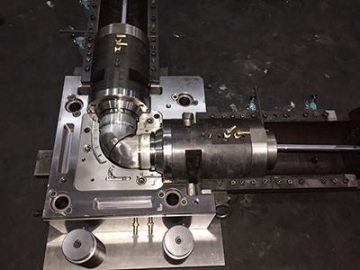

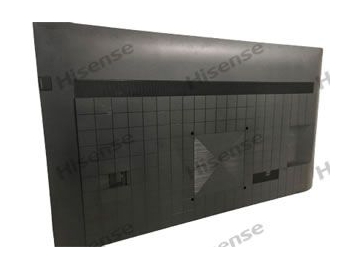

AERO MOLD offers mold design and processing services for plastic products within the home appliance industry, such as those for juice extractors, water fountain shells, refrigerator cabinets, air-conditioner shells, and fan blades. Customers need only provide the design drawings, and our engineer will produce molds that meet your requirements. We will also design the best possible cooling water line based on product shape and appearance in order to obtain the best cooling effect, and shorten the forming period.

Sample Molded Plastic Components

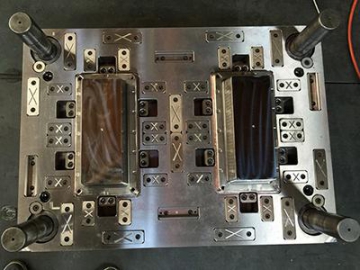

Molded Plastic Components  Plastic Fan Parts

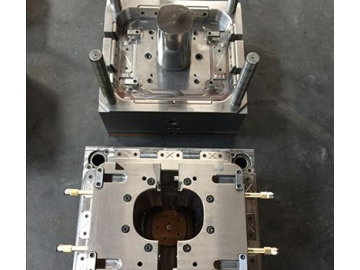

Plastic Fan Parts Plastic Juicer Parts

Plastic Juicer Parts

- Mold base: Plastic mold steels of P20 and 2316 are used for the production of thin wall packaging molds, which avoids mold corrosion and water leaking through any loose connections.

- Mold core, mold cavity: Heat treated 2344 steel, S136 steel and other steels will undergo heat treatment to obtain a hardness of HRC 48-52. This design ensures a long mold life, and helps decrease the risk of mold rusting.

- Insert: Some inserts, such as the heated nozzle, are made using a heat treated S136 or 2083 steel. Not only that, but an insert installed on the top of the male mold's core uses BeCu (Beryllium Copper) instead of other materials, as BeCu is able to withstand the higher temperatures and poor heat dissipation found when inserts are located extremely close to the heated nozzle.

- If required, AERO MOLD can also manufacture thin wall packaging molds made of other materials.

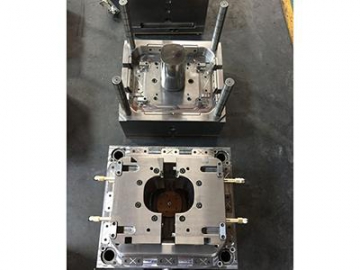

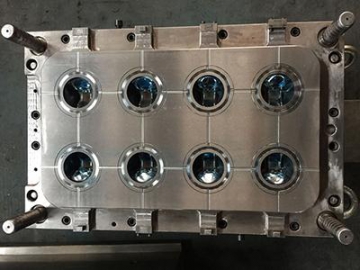

PC Juicer Injection Mold

PC Juicer Injection Mold

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos