Plastic Injection Molding Services

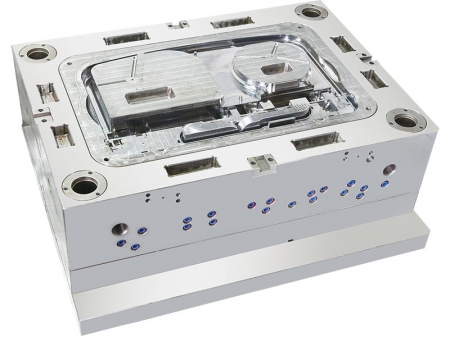

Injection molding is the most cost-effective and efficient way to manufacture large volumes of plastic products. The process involves injecting molten plastic into a mold, which is then cooled and solidified before repeating with the same mold. This fast process reduces the cost per unit of production to just a few dollars or even less. The consistent use of the same mold ensures a high quality, repeatable outcome, while offering more options for materials, colors, and surface textures than alternative methods such as CNC Machining or 3D printing.

We offer a comprehensive service solution to our global customers for injection molding and plastic product needs. Our support begins with the design process and ends with large-scale production. We provide sample creation and a small-scale production trial to ensure a successful end result.

Injection molding is a process that uses an injection molding machine to melt raw plastic materials and inject the molten material into a mold. As the plastic cools and solidifies within the mold, it creates the desired plastic product.

We will reach out to you in the first instance to ensure that your requirements, including aesthetic design, functionality, and delivery timescale meet the demands. After you confirm the pricing with you, we will design and create the mold according to the product drawings you have provided, followed by a mold trial. We’ll then send some sample products for your evaluation; once ratified, we’ll then commence mass production.

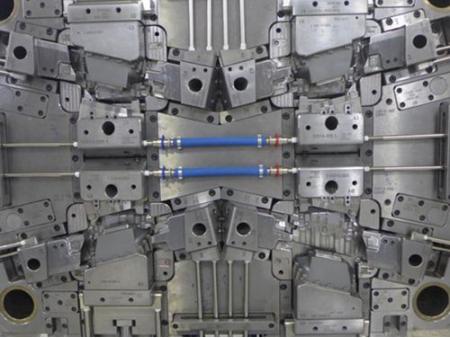

With over 20 years of manufacturing experience and a mature process technology, RZD’s team specializes in insert molding. This method offers superior quality and precision for electronic and automotive parts, whilst keeping costs low. Every step of insert molding is closely monitored to ensure consistent results and customizations are available to meet the needs of customers. Without this level of technical expertise, stable mass production and processing would be impossible.

Insert Injection Molded Parts

Insert Injection Molded Parts Heat Dissipation Shell Of Electric Appliance (With Screws)

Heat Dissipation Shell Of Electric Appliance (With Screws) Insert Molding (Bearing Steel In The Middle)

Insert Molding (Bearing Steel In The Middle)

Overmolding is a special plastic molding process that involves molding a certain plastic material in a primary plastic mold, removing the molded part, and then placing it into a secondary mold for another injection of the same or a different type of plastic material. In more complex cases, multiple molding steps may be involved to achieve the desired shape and design of the plastic product. Overmolding can result in a softer surface texture for the product, and can enhance its functionality and added value. Overmolding finds extensive applications in various fields such as phone cases, protective covers, and automotive headlights.

Two-Shot Molded Part

Two-Shot Molded Part Multishot Molded Part (from outer to inner: white ABS flame retardant PC, 65 Shore TPE, magnesium alloy metal)

Multishot Molded Part (from outer to inner: white ABS flame retardant PC, 65 Shore TPE, magnesium alloy metal)

- ABS

- PC

- PS

- PET

- PP

- PA66

- LCP

- POM

- Silicone

- Rubber

RZD holds a large inventory of these materials, making it easy for us to arrange production at any time. Moreover, we offer customizing design and production services to customers with special requirements for color and structure.