Bright Annealed Seamless Steel Tube

Cold Drawn Steel Tube / Bright Annealed Steel Tube / Seamless Steel Tube

Cold Drawn Seamless Steel Tube, NBK, Bright Annealing, Bright Tube

Dimension range: outer diameter- 3-89mm, wall thickness- 0.4 -10mm

Standard specification: DIN2391, EN10305-1, SAE J524, JIS G3445

Steel grade: ST37.4, ST45, ST52.4, E235, E255, E355, C1010, C1020

Delivery condition: BK, BKW, BKS, NBK

The cold drawn bright annealed seamless steel tube is primarily used in the automotive, hydraulic, machinery, electrical, chemical, ship building, and engineering industries where a high quality steel tube is a must have.

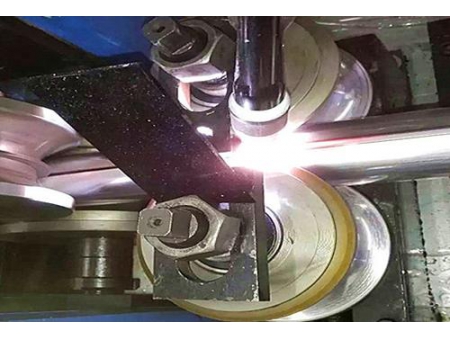

Process Description

High quality carbon steel goes through a refined pull process, with no oxidation bright heat treatments (NBK state). Non-destructive equipment is used in the testing process, and the pipe wall and other special equipment are scrubbed in a high pressure washing, before being coated in a rust prevention oil. Both ends are covered in a dust cover that undergoes a similar treatment process.

Main Features

These cold drawn bright annealed seamless steel tubes feature a high accuracy, and an excellent finish. The outer wall features an oxide layer, and both the interior and exterior surfaces are clean. The steel can withstand a high pressure, cold deformation, flaring, and flattening, all without cracks. The pipes are useful in a variety of complex deformation and mechanical processing needs. The pipe color is light grey with white.

Main Purpose

These cold drawn steel tubes are used in hydraulic systems requiring steel, automotive steel, steel precision industries, and other mechanical industries that feature high performance requirements.

How do we ensure the quality of these automotive steel pipes?

1. We use high quality raw materials. All raw materials are supplied from internationally known steel plants.

2. Each batch of raw material is checked for both chemical and mechanical properties, according to specifications.

3. During the cold drawing process, our inspectors check every bundle three times: once at the beginning of the process, once during the middle, and finally, at the end of the cold drawing process.

4. During the final heat treatment, every bundle has the surface checked, as well as mechanical properties through sampling.

5. Non-destructive testing machinery and manual inspection ensure the 100% quality rate.