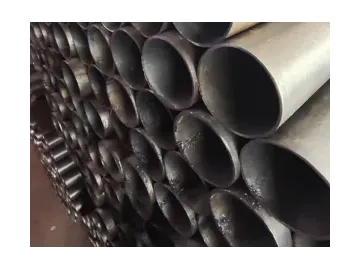

ERW Round Steel Tube

Our ERW round steel pipes are longitudinally welded pipes that are manufactured by forming steel strip into hollow shape, and then welded along the length of the steel pipe. Through the high-frequency electric resistance welding (ERW) process, this type of round steel pipes yields strong joints due to the heat from the electric current can deeply penetrate the metal material. This makes the steel pipe durable and highly customizable, having a wide variety of structural, architectural and construction applications.

As an expert manufacturer of ERW longitudinally welded pipes, we supply custom round steel pipes that are available in a wide range of sizes, such as 21.3mm to 609.6mm in outside diameter and 0.8mm to 17.5mm in wall thickness. Besides, we can also provide ERW carbon steel pipes to satisfy your applications requiring capability of withstanding high pressure.

Standard

- ASTM A53

- ASTM A500

- API 5L

- ASTM A795

- IS065

- BS1387. BS1139,

- GBT 3091 & GB/T13793

Applications

- Structural Pipe/ Structural Tubing

- Pipe Railing

- Scaffolding Pipe

- Fire Fighting Pipe

- Greenhouse Pipe

- Low Pressure Liquid Delivery Pipe

Size

- Outside Diameter: 21.3mm to 609.6mm

- Wall Thickness: 0.8mm to 17.5mm

- Regular Length: 5.8m or 6m or 12m

- Custom Cut-to-Length: 3m to 12m

- Galvanized

- Spray Painted

- Anti-Rust Oiled

- Protective Coated

- Plain End

- Beveled End

- Grooved End

- Threaded End

| DN | Designation of Thread | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | ||

| 15 | 1/2 | 21.40-21.00 | 0.843-0.827 | 1.80 | 0.071 |

| 20 | 3/4' | 26.90-26.40 | 1.059-1.039 | 2.00 | 0.079 |

| 25 | 1' | 33.80-33.20 | 1.331-1.307 | 2.00 | 0.079 |

| 32 | 1-1/4' | 4250-41.90 | 1673-1.650 | 2.00 | 0.079 |

| 40 | 1-1/2' | 48.40-47.80 | 1.906-1.882 | 2.3 | 0.091 |

| 50 | 2' | 60.20-59.60 | 2.370-2.346 | 2.30 | 0.091 |

| 65 | 2-1/2' | 76.00-7520 | 2.992-2.961 | 2.60 | 0.102 |

| 80 | 3' | 88.70-87.90 | 3.492-3.461 | 2.60 | 0.102 |

| 100 | 4' | 113.90-113.00 | 4.484-4.449 | 3.20 | 0.126 |

| DN | Designation of Thread | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | ||

| 15 | 1/2' | 21.40-21.00 | 0.843-0.827 | 2.00 | 0.079 |

| 20 | 3/4' | 26.90-26.40 | 1.059-1.039 | 2.30 | 0.091 |

| 25 | 1' | 33.80-33.20 | 1.331-1.307 | 2.60 | 0.102 |

| 32 | 1-1/4' | 4250-41.90 | 1.673-1.65 | 2.60 | 0.102 |

| 40 | 1-1/2' | 48.40-47.80 | 1.906-1.882 | 2.90 | 0.11 |

| 50 | 2' | 60.20-59.60 | 2.370-2.346 | 2.90 | 0.114 |

| 65 | 2-1/2' | 76.00-75.20 | 2.992-2.961 | 3.2 | 0.126 |

| 80 | 3' | 88.70-87.90 | 3.492-3.461 | 3.20 | 0.126 |

| 100 | 4' | 113.90=113.00 | 4.484-4.449 | 3.60 | 0.142 |

| DN | Designation of Thread | Outside Diameter | Wall Thickness | |||

| (mm) | (inch) | (mm) | (inch) | |||

| 15 | 1/2' | 21.70-21.10 | 0.854-0.831 | 2.6 | 0.102 | |

| 20 | 3/4' | 27.20-26.60 | 1.071-1.047 | 2.6 | 0.102 | |

| 25 | 1' | 34.20-33.40 | 1.346-1.315 | 3.2 | 0.126 | |

| 32 | 1-1/4' | 42.90-42.10 | 1.689-1.657 | 3.2 | 0.126 | |

| 40 | 1-1/2' | 48.80-48.00 | 1.921-1.890 | 3.2 | 0.126 | |

| 50 | 2' | 60.80-59.80 | 2.394-2.354 | 3.6 | 0.142 | |

| 65 | 2-1/2' | 76.60-75.40 | 3.016-2.969 | 3.6 | 0.142 | |

| 80 | 3' | 89.50-88.10 | 3.524-3.469 | 4 | 0.157 | |

| 100 | 4' | 114.90-113.30 | 4.524-4.461 | 4.5 | 0.177 | |

| 150 | 6' | 166.10-164.10 | 6.539-6.461 | 5 | 0.197 | |

| NPS | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | |

| 1/2' | 21.30 | 0.840 | 2.77 | 0.109 |

| 3/4' | 26.70 | 1.050 | 2.87 | 0.113 |

| 1' | 33.40 | 1.315 | 3.38 | 0.133 |

| 1-1/4' | 42.20 | 1.660 | 3.56 | 0.140 |

| 1-1/2' | 48.30 | 1.900 | 3.68 | 0.145 |

| 2' | 60.30 | 2.375 | 3.91 | 0.154 |

| 2-1/2' | 73.00 | 2.875 | 5.16 | 0.203 |

| 3' | 88.90 | 3.500 | 5.49 | 0.216 |

| 4' | 114.30 | 4.500 | 6.02 | 0.237 |

| 6' | 168.30 | 6.625 | 7.11 | 0.280 |

| 8' | 219.10 | 8.625 | 8.18 | 0.322 |

- Leveling

- Ends Cutting

- Slitting

- Recoiling

- Coil Ramp

- Uncoiling

- Leveling

- Ends Cutting

- Trimming & Welding

- Coil Accumulator

- Strip Ultrasonic Testing (UT)

- Forming

- High Frequency Welding

- Welding

- Deburring

- Seam Annealing

- Air/Water Cooling

- Sizing (Round Tube)

- Online Ultrasonic Testing (U.S. Test)

- Straightening

- Flying Cut-off

- Flattening Test

- End Finishing

- Hydrostatic Test

- Appearance Inspection

- Offline Ultrasonic Testing (U.S. Test)

- Marking

- Oil Coating

- Packaging & Storage

- Annual production capacity reaches 500,000 tons.

- Stainless steel processing experience 21 years

- Production scale houses more than 20 production lines