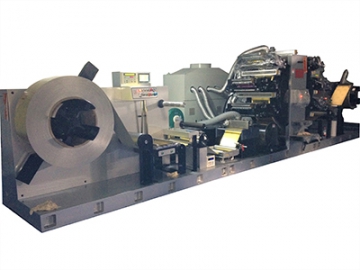

Workbench for Hand Printing (with Printing Dryer)

Shown on this page is employees using screen frames to carry out screen printing on long, flat print tables. The screen printing dryer cures or dries one color, so that the next color to be applied won’t smear or smudge.

The manual flatbed screen printing line includes the screen printing textile dryer and the print table, both of which are added for an improved printing rate and reduced labor intensity. The length, width, and material of the print table can be customized according to specific printing needs.

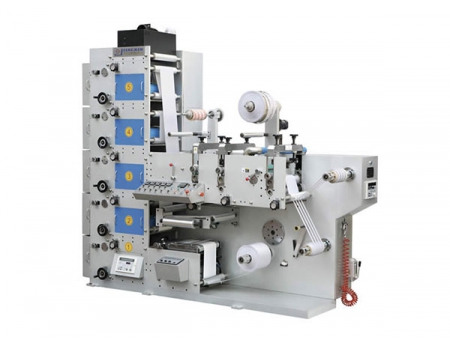

Movable dryer

For customers who need an automated drying process, our mobile dryer is a popular choice, as it can be integrated into the manual flatbed screen printing line and controlled by the micro-computer. When arriving at each printing station, the dryer can be set with the proper drying time and drying mode (flash cure or contact drying). The drying unit is stable, and saves more energy than a typical drying oven.

Print Table

The long, flat table has a rigid steel construction, and its bolted joints allow for easy assembly and disassembly. The table legs are specialized leveling mounts for an easy height adjustment, while ensuring the table stays level. The table surface is made of 10mm tempered glass with the edges sanded to be flat. This screen printing machine can print on heat resistant patent leather, fleece, and 18mm thick block board.

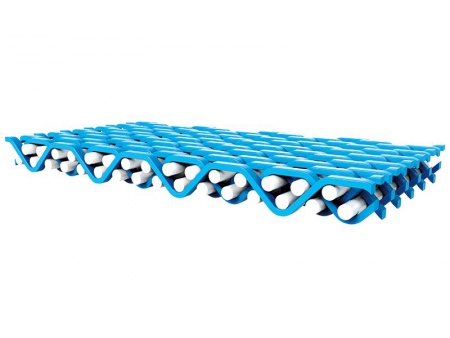

Related Configurations of Manual Flatbed Screen Printing Line

1. Tempered glass

2. Aluminum guide rail

3. Guide roller

4. Conductor bar

5. Current collector

6. Leveling mount

7. Screen frame (with attachments)