Bulldozer DFY-4

The hydraulic system of the bulldozer adopts the pilot control,with little operation force. The pre positive of cylinder reduces the pressureof the system. The control valve is outside and the volume of oil tank islarge, which improve the cooling effect and the reliability of the hydraulicsystem. It has hexahedral cab and side-door engine hood. Having pretty outline,wide vision, a rational overall layout and compact structure, it is convenientto maintain.

The Bulldozer is a upgrade product of bulldozer. It hascharacteristics of semi-rigid suspension, mechanical drive. The main clutch ishydraulic boosted. The articulated point of the implement cylinder is at bothsides of the guard., With hydraulic pilot controlled , electric monitoring,good appearance, it can be used in road building , hydro-electric construction, field modification , port and mine development and other construction .

Main Specifications

Overall dimensions (L × W × H): 5416 × 3297 × 3160 mm (straight)

5566 × 3726 × 3160 mm(angle)

Operation weight: 17.8t (straight); 18.2t (angle)

Flywheel power: 121kW

Max. drawbar pull: 139.6 kN ( straight ); 142.7kN(angle )

(The efficient force depends on weight and ground surface adherence)

Ground pressure (at operating weight): 69KPa

Min. ground radium: 3.9 m

Min. ground clearance: 352.5 mm

Grade ability: Straight 30 °

Side 25 °

Diesel Engine

Type: straight line, water-cooled, with four stroke, pressure boost and direct injection

Cylinders Number-bore diameter × travel distance: 6-126x 130mm

Displacement: 9.726 L

Rated RPM: 1800 r/min

Rated power: 130 kW

Max. torque 870 N • m/1200-1300 rpm

Fuel consumption (at rated working condition)

225 g /kW • h

oil consumption: 1.8 g /kW • h

Admissible altitude ≤ 4000m

Cooling method: closed circulation water cooled

Starting method: electrically starting at 24V pressure

Type: straight line, water-cooled, with four stroke,

Cylinders Number-bore diameter × travel distance: 6-135x 150mm

Displacement: 12.88 L

Rated RPM: 1800 r/min

Rated power: 130 kW

Max. torque 838 N • m/1260 rpm

Fuel consumption (at rated working condition)

224 g /kW • h

oil consumption: 0.7 g /kW • h

Admissible altitude ≤ 4000m

Cooling method: closed circulation water cooled

Starting method: electrically starting at 24V pressure

Main Clutch and Transmission

The flywheel clutch is constantly disengaged with muti-powder-metaldiscs, which is operated by hydraulically boosting,.

The transmission is mechanical double levels controlled with constantly meshedhelical gears, and coupling sleeve shift. It has five speeds FORWARS and fourspeeds REVERSE.

Travel speed (in theory 1800r/min engine speed)

Forward Reverse

First speed 2.5km/h First speed 3.5km/h

Second speed 3.3km/hSecond speed 4.6km/h

Third speed 5.7km/h Third speed 7.9m /h

Forth speed 7.5km/h Forth speed 10.5km/h

Fifth speed 10.61km/h

Steering and Braking

The steering clutch is tighten by pressured springs and separated hydraulicallywith oil-type, multi-powder-metal discs.

The brakes are oil, two-direction floating band with mechanism foot pedals, hydraulicboosted. The steering and braking can be actuated in one control.

Final drive

The final drives are double reduction with spur gear and segment sprocket, whichare sealed by floating oil seal for easy service.

Under carriage System

Inner and outer beam of track roller frame are rectangular section

Track roller (each side):

Singe flange 4

Double flange 2

Carrier roller (each side): 2

Idler (each side) 1

Type of track: single grouser combined Tension mode of track: hydraulic

Pitch: 203mm

Number of shoes (each side) 38 pieces

Width of shoe 500mm

Length of track on ground 2570mm

Sealed and lubricated track

The pitch, numbers and width of track shoes are the same with the general track.

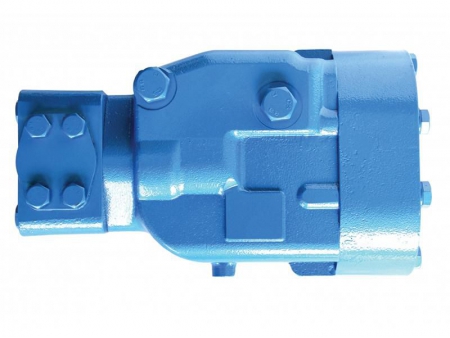

Implement Hydraulic System

It consists of two group gear pump, pilot valve, main valve, cylinders, oil filterand lines.

Pump type: two group gear oil pump

Pump flow:

Front pump: 190L /min Pilot pump: 19L /min

System pressure: 12MPa

Cab

The cab with adjustable seat features low noise and wide visible range and containselectrical fan.

This following different kinds of cabs as follow can be chosen:

Cab with air-conditioner

Cab with Rops

Simple structure canopy

Service Refill

Fill location Capacity (L)

Radiator and diesel engine water: 60

Lubricating system of diesel engine Oil: 25 ( G128 )、20 ( WD615)

Flywheel house, main clutch oil : 35

Transmission, bevel gear case Oil: 95

Final drive (each side) Oil: 24

Implement hydraulic system Oil: 80

Fuel tank Oil: 285

Idle track roller, carrier roller, front idler (each) Oil: 0.35

Blade Specifications

Blade Angle Straight Coal pushing

( Width 3762mm 3297 mm 4240mm

Height 1140mm 1170 mm 1150mm

Max digging depth: 400mm420mm

Max. ground clearance : 1000mm852mm 1000mm

Vertical tilting angle: 9 ° 8.5 ° 9 °

Note: Materials and specifications are subject to change without notice.