Conveyor Idlers

Idlers are key parts of a conveyor belt system, impacting how well and how long the belt runs. Even though they only make up a small part of the conveying system's total cost, the right idlers can make a big difference in how smoothly and affordably the conveyor operates. The idlers manufactured by Yuxin Machinery are made to keep working in tough conditions, from really cold temperatures as low as -40°C to as high as 70°C, and they can work smoothly in places that are dusty or wet.

At Yuxin Machinery, we focus on offering exactly what you need for your conveyor system. Whether you're moving delicate items that need gentle handling or heavy loads that demand more support, we have a range of idlers designed for various applications. We offer idlers that keep the belt stable, absorb shock, stay clean, support the load, and even help keep the belt straight. Each type is manufactured carefully to make sure your conveyor system works as well and as long as possible.

Equal Troughing Idler

This type of idler supports your conveyor belt by evenly distributing material weight, which helps to keep the belt steady and reduces strain. Its design also aids in keeping the belt properly aligned, so everything runs smoothly.

- Solid belt support: The equal troughing idler helps carry the load, making sure the conveyor belt doesn’t have to work harder than it should.

- Enhanced stability: Equal troughing idlers work as the steady hand guiding your conveyor belt. It not only moves the belt along smoothly but also protects the bearings inside from dirt and debris.

- Long-Lasting service: Equal troughing idlers are crafted to decrease the everyday wear on conveyor belts, meaning your system runs smoother for longer, reducing the need for frequent maintenance.

Impact Troughing Set

Our impact troughing sets are installed where materials are loaded onto the conveyor, providing cushioning to the belt's impact zone. Ideal for the demanding environments of coal washing plants, coking plants, and chemical factories, these idlers are crafted for toughness, exceeding the durability of standard metals by more than ten times.

They offer a service life five times longer than regular idlers. Beyond being resistant, these impact troughing sets are corrosion-resistant, flame-retardant, anti-static, and lightweight. These features make our impact idlers stand out in any setting that would wear down ordinary materials quickly. Made from high quality polymer materials, these idlers resist corrosive elements, ensuring a lifespan that's over five times longer than traditional idlers when used in harsh conditions five times longer than the usual idlers.

V-Return Rubber Disc Idler

V-return rubber disc idlers are part of the return idlers category, designed to support the underside of the conveyor belt. With hard rubber discs fitted to these idlers, they are designed to prevent the conveyor belt from slipping off its track. This design is particularly effective for conveyors that handle sticky materials, ensuring smooth and stable operation even under challenging conditions.

Self-Aligning Return Idler

The self-aligning return idler is engineered to keep conveyor belts running straight, which is particularly crucial for systems transporting items. It's installed on the side of the conveyor that carries the load, helping to straighten out the belt whenever it starts to drift off course. This corrective action is key to preventing disruptions in material transport, making the idler a vital component for maintaining the efficiency and reliability of conveyor operations.

Self-Aligning Troughing Idler

The self-aligning troughing idler adds an additional centripetal force compared to standard aligning idlers, enhancing its ability to correct belt misalignment more effectively. This feature makes it an ideal choice for ensuring the conveyor belt stays centered, reducing downtime and maintenance costs associated with belt misalignments.

Hydraulic Self-Aligning Idler

Hydraulic self-aligning idlers use sensors to detect any deviation in the conveyor belt's path and employs hydraulic principles to adjust the angle of the idler set, effectively correcting the misalignment. This sophisticated system ensures that the conveyor belt remains centered, enhancing both the efficiency and reliability of the conveyor operation.

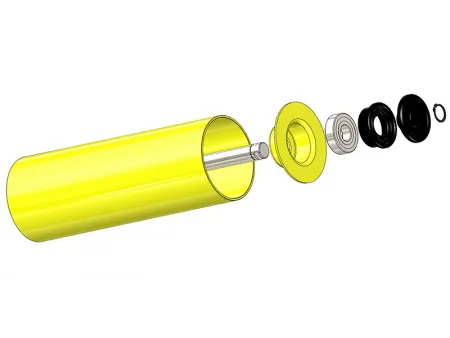

Idler Rollers are crucial components in conveyor systems, designed to support the conveyor belt and enable its smooth rotation along the system. Their main function is to provide support, reduce the belt's resistance during movement, and maintain the belt's sag within acceptable limits, ensuring stable and reliable operation. Idler rollers come in various designs to suit different operational needs, including standard idlers, impact idlers, comb idlers, conical idlers, spiral idlers, and friction idlers.

Rubber Impact Idler Roller

We offer rubber impact idler rollers that are specially designed for the material drop area of conveyor systems, where it plays an important role in absorbing the impact of materials as they fall onto the conveyor belt. This type of roller is particularly useful in corrosive environments like coal washing plants, coking plants, and chemical factories. It features toughness more than ten times that of ordinary metals and has a lifespan five times longer than traditional rollers. Its corrosion resistance, flame retardancy, anti-static properties, and lightweight design make rubber impact idler rollers an ideal choice for mining operations.

Rubber Disc Return Roller

Rubber disc return rollers are an essential upgrade for conveyor systems, specially designed to enhance belt life and cleanliness. This type of rollers is equipped with rubber discs that significantly reduce the direct contact between the conveyor belt and the roller's steel frame, thereby minimizing wear. These rubber discs also aids in the removal of adherent materials from the belt, maintaining its cleanliness and operational efficiency.

Tapered Troughing Idler Roller

The tapered troughing idler roller stands out for its exceptional ability to guide and keep the conveyor belt perfectly centered. Offered in both top self-aligning and bottom self-aligning configurations, these rollers are known for their resistance to wear, ensuring an extended lifespan. Their design is notably lightweight, reducing rotational inertia and thus enhancing the smoothness of operation. Designed meticulously, they feature effective sealing to block out contaminants. Additionally, their outstanding resistance to corrosion makes them suitable for use in demanding settings.

Steel Spiral Return Roller

Designed with innovation as a main focus, the steel spiral return rollers significantly prolong the lifespan of conveyor belts. Featuring a steel spiral wrapped around a conventional roller body, this design helps to avoid direct interaction between the conveyor belt and the roller's steel surface. Instead, the spiral steel touches the conveyor belt, dislodging sticky substances and minimizing belt wear. This innovative approach not only maintains the belt's cleanliness but also greatly prolongs the durability of the belt's exterior.

Friction Roller

Engineered to synergize with troughing idlers, the friction roller is integral in mitigating conveyor belt misalignment and ensuring uninterrupted operational stability. This specific roller type modifies or amplifies the frictional interaction between itself and the conveyor belt, effectively rectifying any propensity for the belt to deviate from its prescribed course. By upholding precise alignment, the friction roller is instrumental in facilitating the seamless and efficacious performance of the conveyor system, substantially reducing incidents attributable to belt misalignment.

Polyethylene Idler Roller

We designer our friction rollers to work hand in hand with troughing idlers, providing a critical solution to the challenge of conveyor belt misalignment. This roller type is capable of adjusting or increasing the friction between the roller and the conveyor belt. Such adjustments are necessary to correct any tendencies of the belt to stray from its intended path. By maintaining correct alignment, our friction rollers play an important role in ensuring the conveyor system's operation is smooth and efficient, thereby significantly minimizing issues caused by belt misalignment.