Conveyor Pulleys

Conveyor pulleys are key components in belt conveyor systems, significantly enhancing efficiency. Their main function is to reduce the friction between the material being conveyed and the conveyor belt itself. This reduction in friction lowers the belt's resistance, speeds up material movement, and boosts overall conveying efficiency. Additionally, pulleys play an important role in reducing energy costs by minimizing energy consumption during operation.

Pulleys also contribute to the safety of conveyor systems. Their smooth rotation helps to decrease friction and vibration of the materials in transit, minimizing the risk of material spillage and wear. This, in turn, reduces the likelihood of accidents, making for a safer conveying process.

At Yuxin Machinery, we understand that every conveyor system has its unique requirements. That's why we offer the option to customize pulleys to fit your specific needs, enhancing both the efficiency and safety of your conveyor system.

Conveyor pulleys are necessary in the operation of conveyor systems. Here's how they contribute:

- Supporting weight: They hold up the weight of the conveyor belt and the materials it transports, using rolling bearings for smooth movement.

- Power transmission: As part of the drive system, pulleys transfer the motor's power to the conveyor belt, moving the materials along.

- Tension adjustment: They help adjust the tension of the conveyor belt, ensuring it has the right tightness to operate efficiently without slipping or sagging.

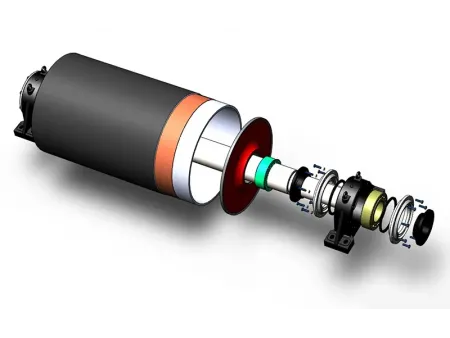

Conveyor pulleys are available in various types, each designed to fulfill specific requirements based on their functionality, structure, surface treatment, and how they connect to the system. This ensures that whatever your conveyor system's needs, there's a pulley designed to meet them.

- Head Drive Pulley

- Bend Pulley

- Spiral Wing Pulley

- Traditional Wing Pulley

- Engineered Pulley (Pulley Lagging)

- Drum Pulley

- Self-Aligning Return Roll

- Herringbone Wing Pulley