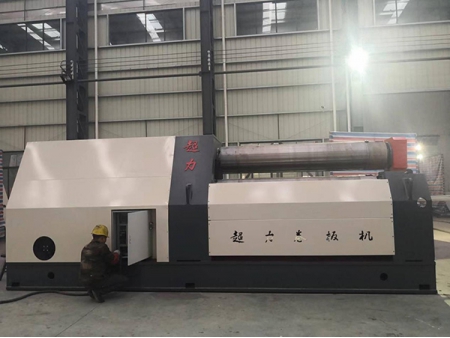

4-Roll Plate Bending Machine

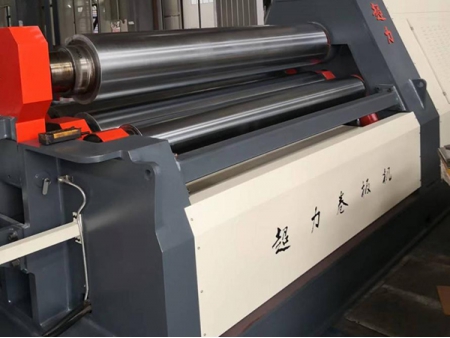

The CNC four-roll plate bending machine features a pre-bending function for the ends of metal sheets, allowing efficient single-load processing without the need to turn the material. The top working roll serves as the main driving roll, while the movement of the lower and side rolls is hydraulically driven. This setup is controlled by a computer to ensure precise automatic leveling and to display the adjustments on a screen for easy monitoring.

The plate bending equipment’s tilting and resetting operations are powered hydraulically, and a balancing mechanism at the upper roll's tail end aids in the easy removal of the workpiece and cylindrical shapes after rolling. For added convenience and flexibility, our plate bender is equipped with a movable independent control console that allows operators to adjust positions as needed.

Safety is a priority for us when designing and manufacturing our plate bending equipment, which is why our four-roll plate bending machine is equipped with interlock devices to prevent accidents during operation. With its comprehensive features, high precision, and user-friendly interface, our CNC plate benders are an ideal solution for modern CNC plate rolling requirement, offering both high efficiency and reliability in metal forming tasks.

With a rectilinear guide system, the forming rolls are transmitted and forced directly into the hydraulic cylinder. There are no load-bearing wear points or torsional stresses in the 4-roll plate rolling equipment interfering the roll parallelism and accuracy, which has contributed to a long service life, consistent rolling result, and convenient maintenance. The centerline of the forming roll is close to that of the pinch roll, allowing the flat areas associated with pre-bending to be small and consistent. In addition, Chaoli has regulated the direct-acting hydraulic cylinders for pre-bending to the maximum rolling capacity.

The rolls of the plate bending machine are independently driven by planetary gear drives, eliminating the complicated transmission systems which are not energy efficient. More than 98% of the created energy is delivered to the roll surface. Besides, clutches and complicated synchronization devices are also of no necessity.

Spherical roller bearings are extremely energy efficient, which have eliminated bushings and the necessary running tolerance. The energy loss among which 25-30 % is taken up by bronze bushings for overcoming the inherent friction is negligible.

Our 4-roll plate bending machine is widely used by industries looking for precision and versatility in rolling operations. Ideal for sectors such as energy, transportation, oil, petrochemicals, boiler manufacturing, shipbuilding, hydropower, and metal structures, this plate bender excels in creating perfect cylindrical, arc, conical, square, and various uniquely shaped workpieces. Its capability to handle a wide range of shapes makes it indispensable for projects requiring high precision and efficiency.

- Mixing drum of concrete mixer truck

- Bridge casings

- LNG storage tank

- Boilers

- Steel silo

- Drum dryer

- Box truck body

- Pressure vessel

- T1.2×H1200×Ø150 ×Ø400mm (SS304)

- T1.2×H1200×Ø150 ×Ø400mm (SS304)

- T3×H1250×Ø220 ×Ø1300mm (SS304)

- T6×H3000×Ø450 ×Ø1500mm (SS304)

- T8×W2500 ×Ø5800mm (stainless steel)

- T12×W2000 ×Ø800mm (aluminum alloy 5052)

- T35×W2000 ×Ø800mm (Q355)

- T30×W1600 ×Ø800mm (Q355)

| Model | Yielding limit of plate (MPa) | Max. thickness (pre-bending thickness) (mm) | Max. rolling width (mm) | Upper roller diameter (mm) | Bottom roller diameter (mm) | Lateral roller diameter (mm) | Motor power (kW) | Min. rolling diameter under full loading (mm) |

| | 245 | 4(3) | 1500 | 150 | 130 | 120 | 4 | 250 |

| | 245 | 5(4) | 1500 | 160 | 160 | 150 | 4 | 260 |

| | 245 | 6(5) | 1500 | 186 | 180 | 150 | 5.5 | 285 |

| | 245 | 8(6) | 1500 | 210 | 180 | 150 | 5.5 | 320 |

| | 245 | 6(5) | 2000 | 210 | 180 | 150 | 5.5 | 340 |

| | 245 | 8(6) | 2000 | 230 | 210 | 170 | 7.5 | 380 |

| | 245 | 6(5) | 2500 | 240 | 220 | 170 | 7.5 | 400 |

| | 245 | 10(8) | 2000 | 250 | 230 | 170 | 7.5 | 430 |

| | 245 | 8(3) | 2500 | 250 | 230 | 170 | 7.5 | 440 |

| | 245 | 12(10) | 2000 | 270 | 250 | 200 | 11 | 480 |

| | 245 | 10(8) | 2500 | 280 | 250 | 200 | 11 | 490 |

| | 245 | 16(12) | 2000 | 330 | 300 | 240 | 15 | 560 |

| | 245 | 12(10) | 2500 | 320 | 300 | 240 | 15 | 550 |

| | 245 | 20(16) | 2000 | 350 | 330 | 250 | 18.5 | 600 |

| | 245 | 16(12) | 2500 | 360 | 340 | 250 | 18.5 | 600 |

| | 245 | 20(16) | 2500 | 380 | 340 | 280 | 22 | 650 |

| | 245 | 25(20) | 2000 | 380 | 340 | 280 | 22 | 650 |

| | 245 | 25(20) | 2500 | 420 | 380 | 320 | 30 | 750 |

| | 245 | 20(16) | 3000 | 420 | 380 | 320 | 30 | 750 |

| | 245 | 30(25) | 2500 | 480 | 460 | 340 | 37 | 850 |

| | 245 | 25(20) | 3000 | 480 | 460 | 340 | 37 | 850 |

| | 245 | 40(32) | 2500 | 520 | 500 | 400 | 45 | 1000 |

| | 245 | 40(32) | 3000 | 560 | 540 | 420 | 45 | 1200 |

| | 245 | 45(35) | 3000 | 600 | 560 | 460 | 55 | 1500 |

| | 245 | 50(40) | 3000 | 620 | 600 | 470 | 55 | 1700 |

| | 245 | 60(50) | 3200 | 650 | 620 | 500 | 75 | 1800 |

| | 245 | 70(55) | 3200 | 700 | 650 | 560 | 90 | 2000 |

| | 245 | 80(65) | 3200 | 800 | 750 | 640 | 90 | 2000 |

| | 245 | 100(80) | 3200 | 860 | 800 | 700 | 110 | 2000 |

| | 245 | 120(100) | 3200 | 930 | 900 | 750 | 130 | 2500 |

| | 245 | 150(120) | 3200 | 1000 | 950 | 800 | 150 | 3000 |

The dual-drive motors feature mechanical brakes and bidirectional balance valves, ensuring enhanced safety with dual braking mechanisms. This improved design offers high durability and reliable performance.

Equipped with an advanced heavy-duty linear guide structure, providing higher load capacity and the ability to withstand greater weight and torque.

The high-quality roller shafts are made from forged materials and undergo rigorous heat treatment and hardening processes. The surfaces are then polished to guarantee a more efficient performance.

The CEIA® pre-bending system offers exceptional results, ensuring the straight edge at the plate head is minimized to within 1.5 times the plate thickness, enhancing overall bending precision.

- By integrating the cylinder and slider into a single cast unit, the contact area between the slider and the rail is significantly increased, enhancing the stability of the side roller movement.

- Combining the cylinder and slider shortens the length of the rail and reduces the overall height and center of gravity of the bending machine, leading to lower construction costs.

- The inverted installation structure protects the seals, extending the lifespan of the cylinder and reducing the frequency of maintenance and repairs.

Thanks to the innovative CECB® bending system, it is possible to produce cones with much smaller diameters, enhancing precision and versatility in metal forming.

Our high-standard, independently developed hydraulic system includes switch valve control, proportional valve control, and electro-hydraulic servo systems.

Equipped with advanced Siemens PLC systems (S7-200, S7-1200) and high-end IPC industrial control systems for superior performance and reliability

- Forged roller shafts made from 42CrMo material

- The welded brackets are annealed to relieve stress

- Our rollers undergo advanced heat treatment processes, including tempering, quenching, and precision polishing, to ensure superior durability and performance

- Air cooling system

- Upper support (supports bending of workpieces with large diameters)

- Lateral support

- AC cooler system

- Hydraulic accumulator