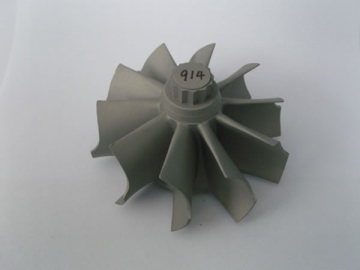

Compressor Wheel

A Brief Introduction to Our Compressor Wheel

The gasoline engine has a wide speed range and a big change of air flow, so the compressor wheel of turbocharger has a complex wheel design of curved surface. There are totally 12-30 pieces of compressor wheel arranged radially in the turbo, with a thickness of less than 0.5mm per piece.

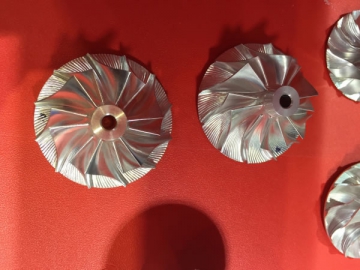

Material of Compressor Wheels

We make use of C355 aluminum and advanced low pressure casting technique, providing a uniform thickness of each wheel and realizing high production quality.

Processing Techniques

The processing techniques mainly include heat treatment, sand blasting, cutting, polishing and so forth.

Product Testing Instruments

For the purpose of avoiding defective products and achieving a high quality, our company invested a lot in sophisticated and functional instruments and devices, including professional physical and chemical laboratory, fluorescent penetrant inspection device, spectrum analyzer, metalloscope, Brinell hardness tester, measurement project and so forth.

Sale Performance

To date, our firm is able to monthly manufacture 100,000 pieces of turbine wheels and compressor wheels. Good performance and high security ensure that our products are sold to more than 100 domestic turbocharger companies and component plants. Not only this, our products are also exported overseas, such as America, Europe, Oceania, Africa, Asia and other 10 countries and regions. Our products have built reputation and became favorites in these countries. Currently, our company has developed about 300 types of turbine wheels and compressor wheels. Also, we are able to research and develop new products on client's request.

Sizing Table