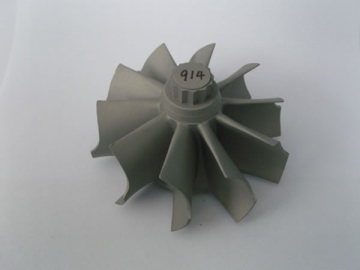

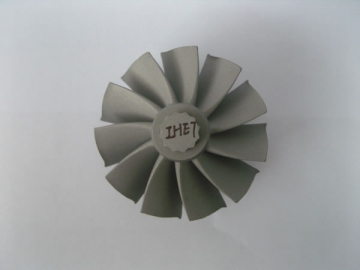

Turbine Wheel

Production Introduction

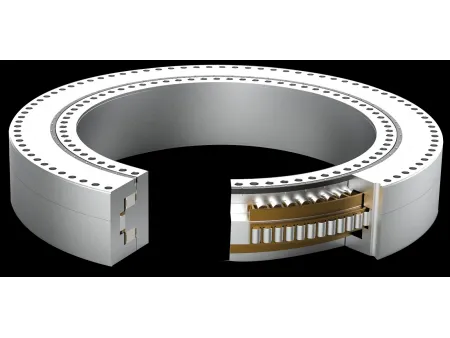

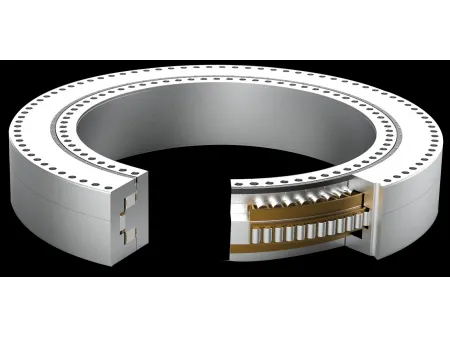

Turbo usually functions as a fan and is installed in the engine of car or airplane. It is able to improve the engine capacity by utilizing exhaust gases and transferring the fuel vapor into the engine. It's a kind of rotary power machine that transforms the energy of gas into mechanical work. It plays a vital role in the aircraft engines, gas turbines and steam turbines.

Materials of Turbine Wheel

Our turbine wheel adopts silica sol and medium temperature wax, achieving excellent and stable performance. The medium temperature wax is especially designed and produced for turbine wheels by American C-M Group. The raw materials are K-418, and K213 high temperature alloys manufactured by Beijing Antai. After two-stage vacuum melting and casting, high quality turbine wheels are finished.

Manufacturing Process

The main processing techniques include heat treatment, sand blasting, cutting, polishing, electroplating, power spraying, anodizing and galvanizing.

Producing and Testing Instruments

In order to avoid defective products and achieve a high quality, our firm invested a lot in sophisticated instruments and devices, including professional physical and chemical laboratory, fluorescent penetrant inspection device, spectrum analyzer, metalloscope, Brinell hardness tester, measurement projector and so on.

Foreign Businesses

Currently, our company is able to manufacture 100,000 units of turbine wheels per month and to provide good quality turbine wheels and compressor wheels for over 100 domestic companies. Not only that, our products are exported worldwide, including America, Europe, Oceania, Africa, Asia and other countries and regions. In these countries, our products receive favorable acclaims due to the energy saving and power enhancing. To date, our company researched and developed over 300 types of turbine wheels and compressor wheels. We will also design and manufacture products in client’s special request.

Product Price

Thanks to our efficient production lines, we are able to manufacture a wide array of products and components. Thus, we can provide flexible product prices as well as good service.

Professional Service

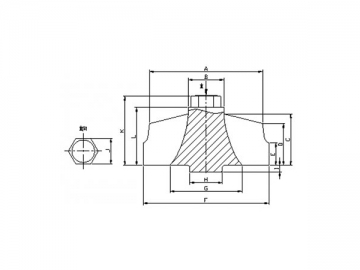

Our company also offers OEM and ODM service. If you want to cooperate with us, please provide us with all your technical drawings and detailed requirement, such as material type and grade, processing requirement, surfacing treatment, heat treatment, mechanical properties and so forth. Our technicians will reply you with a final offer within 3-5days.

Delivery and After-sales Service

Our company strictly complies with the contract and designs a reasonable production plan, ensuring our products delivered in a timely fashion. That’s why 98% of the customer orders are completed on time. We provide several transportation types, including marine transportation, air transportation and express delivery. If we have stocks in our warehouse, your products will be sent to our clients even sooner. Generally speaking, the delivery cycle of new products is about 45 days while the delivery cycle of traditional products is 30 days.

Fengxuan has a strong confidence in our products and provides excellent after-sales service for our clients. In normal service, if any problems or damages caused by material, process, manufacture and design occur, we promise to change and refund for clients. In addition, we will send you 1% of wearing parts for free, considering the tight supply of these components.

Please feel free to contact with us, we are always ready for you!

Sizing Table of Turbine Wheels